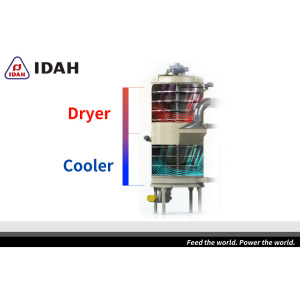

Drying and Cooling shrimp feed in One machine

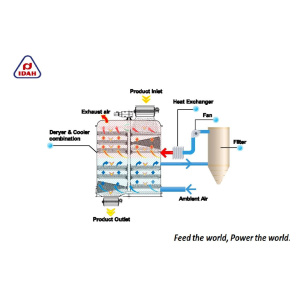

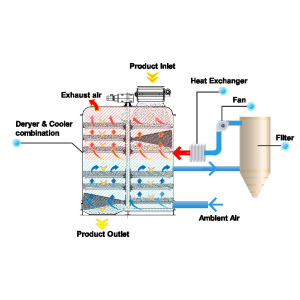

So what is the latest technology in drying and cooling shrimp feed? We considered all the requirements and the experience in the field and have developed a Generation 3 (G3) pelleting system that incorporates the dryer and cooler (TK-series) in one machine

READ MORE

Drying and Cooling of Bakery Grist at Its Finest with Carousel Dryer-Cooler (Published in dei-Germany).

Drying of bulk material can be a tricky and interesting process, simply because of the volume and number of material is larger. In order to provide an optimal drying process, it is important to understand the nature of the material to be dried. Some material may require gentle mechanical and thermal handling.

One example of the material is bakery grist (blend of wheat or grains). This is a pre-processed dough-like-mass consist of coarsely ground cereals, intended for baking whole-meal bread. When entering the dryer, it is quite pasty and sticky. The dryer-cooler (figure 1) is expected to lower the moisture down to around 10%. The drying temperature must not exceed 50°C in order to preserve the nutritive value.

READ MORE

900 Ton per day shrimp feed turn-key project / India

This customer incorporate ZP-125B & ZP-150 ultra-fine grinder in their post-grinding system. This ultra-fine powder will increase feed cooking, thus improving feed digestibility. They also used our twin paddle mixer for better homogeneity when mixing micro-nutrients.

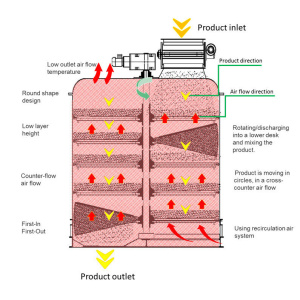

Moreover, in 2017, they started using the IDAH Vertical Cross Counterflow Rotary (VCCR) dryer designed for uniform drying purposes. The tilting trays and the airflow design, enable each pellet to be mixed well and achieve the suitable temperature treatment throughout the dryer.

READ MORE

Carousel Dryer and Cooler for Food

Besides energy consumption, the drying process will change the color, texture, odor, and other properties of solid products. Hence it is of the utmost importance for a dryer to dry effectively with low energy consumption.

The carousel dryer is developed to dry the food with small space requirement, quick product change, lower energy requirement, lower air volume requirement, gentle tumbling across the drying deck, and uniform moisture.

READ MORE

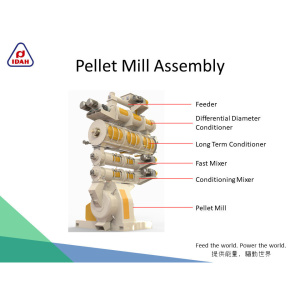

Pelleting process for high-quality shrimp feed (Video)

The production of high-quality shrimp (or prawn) feed is a series of complex and versatile processes. Shrimp feed pelleting is well known in Asia as the most economical way and it dominates the market. In China and India, the shrimp feed (for L. vannamei and P. monodon) market grew exponentially in these few years. Through this presentation, IDAH will guide you to the world of shrimp feed pelleting. In general making shrimp feed is influenced by good formulation and good processing, but the factory floorplan is also accountable for the shrimp feed quality.

READ MORE

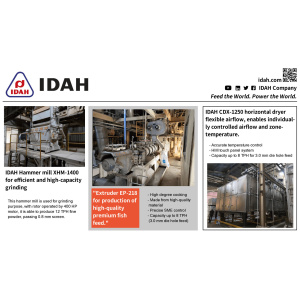

Commissioning of the Fish Feed Plant in Indonesia

Another successful commissioning of the fish feed plant in Indonesia. This fish feed plant utilizes the latest technology from IDAH. The main machines supplied include the hammer mill XHM-1400, extruder EP-218, horizontal dryer CDX-1250, and vacuum coater VC-2000. This production line is intended for production of 8 ton per hour floating fish feed with 3.0 mm hole size

READ MORE

Carousel Dryer - Reliable and Easy Moisture Control (Video)

Carousel Dryer - Reliable and Easy Moisture Control (Video)

Have total control over your dryer investment and energy consumption in your plant!

IDAH considers all of your process requirements FIFO system, moisture uniformity, efficient energy transfer, and easy operation to provide the suitable Carousel Dryer for your industry.

READ MORE

Carousel Dryer in The Production of Shrimp Feed

The carousel drying or cooling process was first used for cooling in the feed industry at the end of the 1970s. The devices have been manufactured by the Taiwanese system manufacturer IDAH from Suao since around 2011 and have been adapted to today's quality standards in a continuous improvement process.

READ MORE

Fish Feed

In order to support provide a balanced and stable feeding for the farmed fish, many producers have shifted to manufactured pellets. Based on the behaviour in the water, fish feed can be divided into floating feed, slow-sinking feed, and sinking feed. IDAH offers you extrusion and pellet mill to produce high quality fish feed.

READ MORE

Drying

What criteria are essential for you to consider before making your selection?/

There are a lot of dryer options available in the market. Are you looking for a dryer with high reliability, energy-efficient, easy moisture control, and quick product changeover? Then IDAH T-series and CDX-series dryer is the best selection for you.

READ MORE

Post-conditioner and Carousel Dryer System for Shrimp / Thailand

With a series of research and development, IDAH has perfected the carousel drying technology in shrimp feed drying. We have delivered more than 40 carousel dryers which are used in aqua feed production.

The limitation of the shrimp feed pelleting is the mash moisture during pelleting. Lower pre-conditioned mash moisture (12-13%) will lower cooking in the mash compared to mash with higher moisture (15-16%). Higher cooking in the mash will result in better pellet integrity, pellet density, and water stability in water.

READ MORE

Carousel Dryer for Pet Food Drying / Germany

An actual result that we obtain from the premier producer of commercial pet foods in Germany. IDAH carousel dryer has a round shape for uniform airflow and gentle drying process through tumbling of the dryer through multiple layers of rotating perforated screen segments design.

READ MORE

Carousel Dryer for Drying Bakery Grist / Germany

Carousel technology is a proven technology used for many different industries. Bakery grist can be dried by the combined dryer/cooler, lowering the moisture from 14% down to 10% at the outlet. IDAH considers all of your process requirements, moisture uniformity, efficient energy transfer, easy operation, and minimal down-time to select the suitable Carousel Dryer for your industry.

READ MORE

The Carousel Dryer - 30 years proven technology

For the past 40 years, IDAH designs and manufactures equipment and process lines for the aquafeed and pet food industries. In 2011, IDAH started focusing on the Carousel Dryer technology. Our team of expert Engineers has worked intensively to improve the Carousel Dryer technology even further to increase the drying process efficiency. The Carousel Dryer delivers outstanding performances when compared to traditional dryers. The main advantages of choosing a Carousel Dryer are:

• All the products undergo the same drying conditions, resulting in very uniform and steady drying.

• Optimal counter-flow heat transfer, resulting in low energy costs.

• Quick changeovers in a controlled way, lessen product contamination.

READ MORE

Extrusion and Drying solution / Thailand

This well-known feed company in Thailand has 2 factorys both in Saraburi and Phetchaburi. These 2 factories inlude 6 floating fish feed lines, 4 shrimp feed lines, 5 poultry feed lines and 1 pet food line.

READ MORE

A New Generation Dryer, Developed for The Shrimp Feed Industry

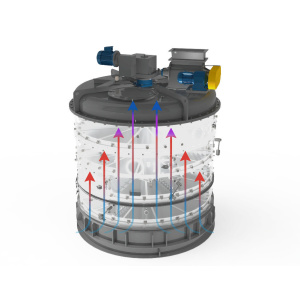

A new generation, developed for the shrimp feed industry, multi-deck carousel dryer/cooler is designed for better uniformity and optimum moisture control.

This compact dryer-cooler has an advanced air system, utilizing the air from the cooler into the dryer air system, thus increases the overall efficiency, and reduces 50% of the exhaust air volume.

The moisture control is performed on the finished cold product done by First-in-First-out (FIFO) product flow with a short overall retention time.

Easy, quick, and accurate moisture control has a big impact on product quality and cost price.

READ MORE

New way of drying shrimp feed

In a modern shrimp feed pelleting process increasingly more liquids are added into the mash feed. This in combination with long term steam conditioning is increasing gelatinization and water stability for a better end product quality. Recipe cost optimisation can be limited if there are drying capacity restrictions. In a lot of situations moisture removal with only cooling is not enough anymore and an extra drying step is required. Moisture control is more and more crucial for quality and cost price reasons.

READ MORE

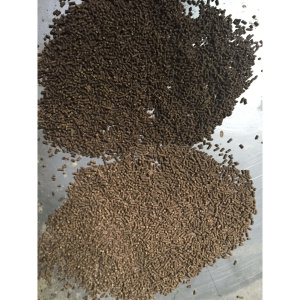

Rising Star in Shrimp Feed Production / India

This customer in India started to purchase our shrimp feed production line back in 2015, with the initial investment in 2 production lines. In 7 years, they have purchased additional 8 production lines, which are divided into 5 production towers in two manufacturing locations, estimated annual production of 180,000 tons. Their shrimp feed size ranges from 1.0 – 2.0 mm size.

READ MORE

Good Dryer Design For High Quality Aquafeed

Nowadays, in the fiercely competitive market environment, every miller uses a similar process as well as ingredients, therefore, the product quality and manufacture cost become the thread of the competition. Overview of the process, dryer performance plays a critical role in this game. For selecting a suitable dryer, two main issues need to be considered, first is average moisture control from dried products and the second is energy efficiency, both are related to the water!

READ MORE

Seminar on Aquaculture Solution and Technology 2018 in India

This seminar was held on August 11, 2018, in Vijayawada, Andhra Pradesh, India.

In 1994, Taiwan ranked 9th in aquaculture production and 6th for the production value on the global scale. Taiwan’s technology has made remarkable contributions to the development of the world’s shrimp farming industry. Taiwan is also known as the “Kingdom of Shrimp Farming” and has been the world’s leading position in terms of both yield and output.

READ MORE