Efficient Mixing Solution from IDAH

IDAH designs and manufactures a single paddle mixer, twin paddle mixer,

single ribbon mixer, and double ribbon mixer. Among our mixer lines, the

twin paddle mixer is the most efficient one.

Finer details and more features are added to IDAH twin shaft

mixers such as pre-assembled spray nozzles with compressed air for pipe

cleaning, hygienic design double-walled stainless steel material for the

food sector application, and incorporation of load-cell. Various sizes

are available, from laboratory scale up (20 liters) to industrial-scale

(5000 liters).

Mixing Action and Changes of Coefficient of Variance (C.V.)

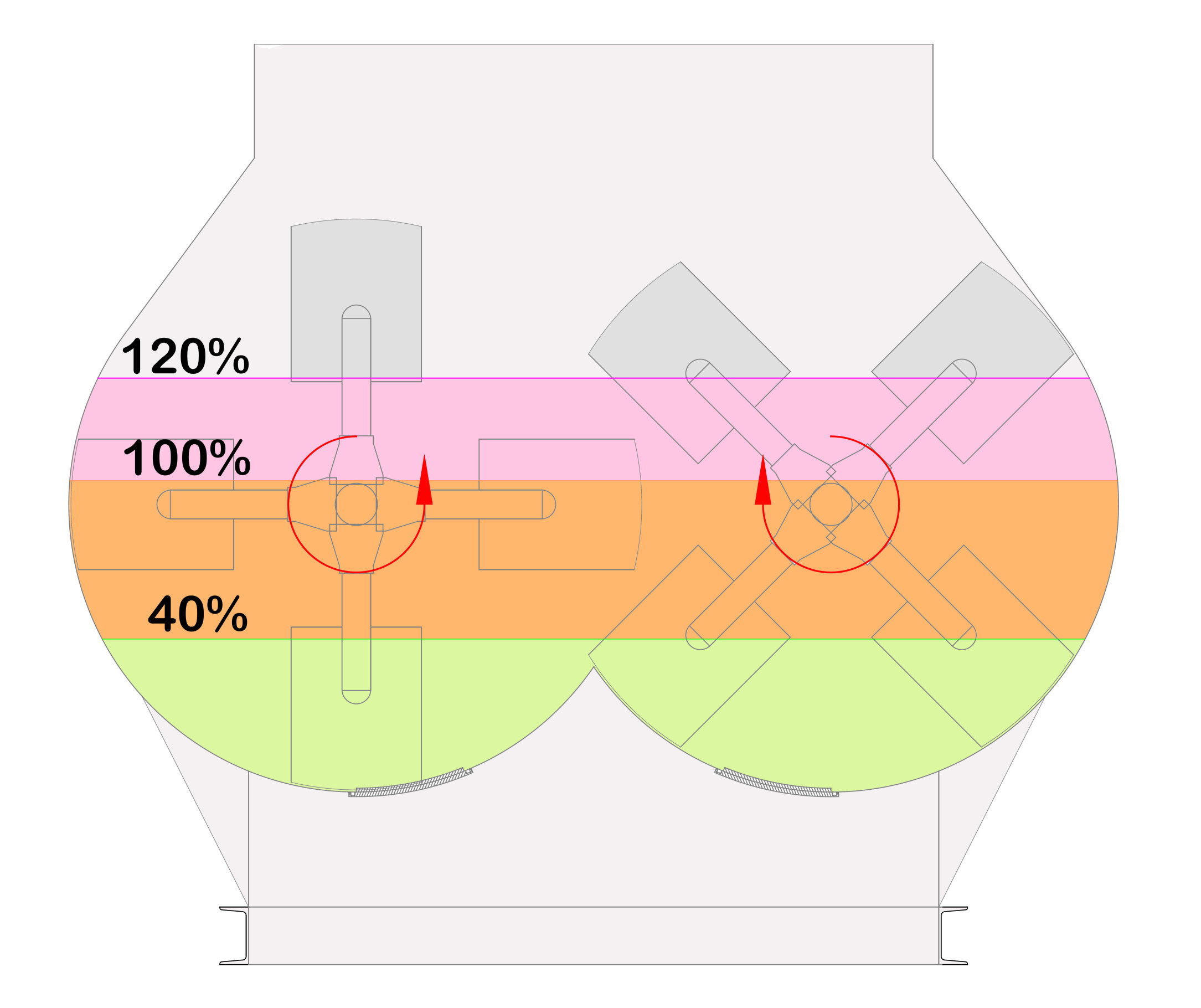

Mixing is an action of tumbling, rotating, and distributing to incorporate ingredients with unique characteristics and phases. In general, there are batch type and continuous type mixers. The twin paddle mixer comprises two opposing rotating shafts with multiple paddles arranged at a certain angle that will distribute the material top to bottom and corners to center for mixing action. A fully open discharge door ensures that material will not be left behind. The design of the paddles can guarantee low shearing, efficient, and fast mixing action for powders, pellets, grains, and granular materials.

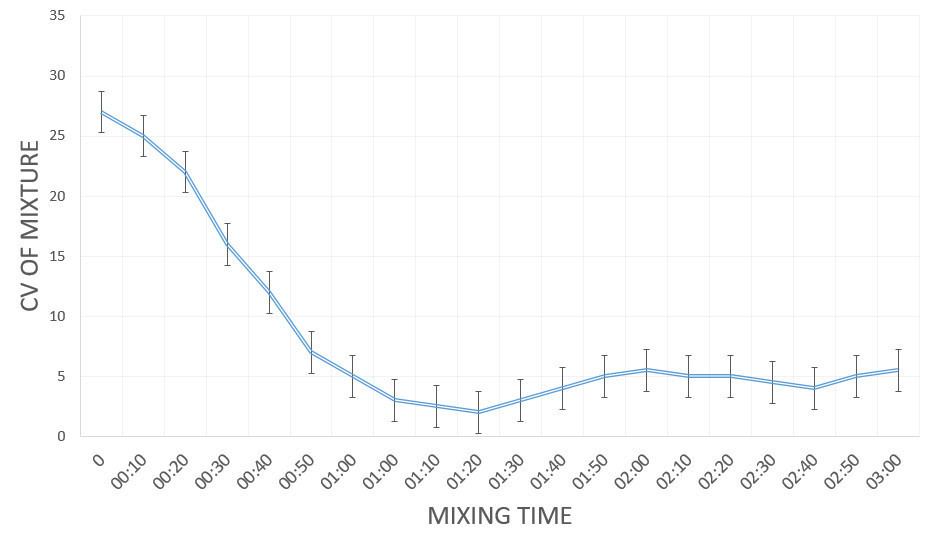

For every mixture, there is an optimal mixing time, where the material will have the lowest C.V. Usually mixing time will be around 60 up to 120 seconds. Further mixing will only lead to segregation.

Features of Twin Paddle Mixer

The mixing chamber of the twin paddle mixer resembles a water droplet shape. The angle ensures less to no material sticking on the wall. This mixer can operate with a flexible loading rate from 40% up to 120% of the normal operating capacity with one machine. The movement of the paddle ensures material from both sides will be directed to the middle part and mixed.