Carousel Dryer in The Production of Shrimp Feed

This article is published in Mühle & Mischfutter 158 Booklet 9 May 6, 2021

Feature of carousel energy:

Carousel dryer-cooler offer a number of advantages on a fixed

installation area

-You use save the installation space by reducing floor height

-By transporting the product through several decks of drying trays, very

uniform drying and cooling is achieved

-In a combination of drying and cooling, the warm cooling air can be

used directly for drying, which saves energy

-The coolers combine the advantages of the counterflow principle with an

additional material rotation for crossflow. Almost every single

granulate receives the same gentle treatment

The carousel drying or cooling process was first used for cooling in the

feed industry at the end of the 1970s. The devices have been

manufactured by the Taiwanese system manufacturer IDAH from Suao since

around 2011 and have been adapted to today's quality standards in a

continuous improvement process.

In Asia region, shrimp feed is generally produced by pelleting system.

Pelleting is known to be able to produce pellets with high density, so

it is easier to produce sinking feed. There are some limitations when

using pellet mill, one of the most profound limitation is the moisture

content of the raw material, which will affect the cooking of starchy.

Starch cooking is affected by three factors, moisture, heat and time.

So, limitation in one of the factor means a limitation in the cooking of

starch. Another limitation is when the moisture reached 16-18%, die

plugging will occurs more frequently (Bortone, J.E., 2001).

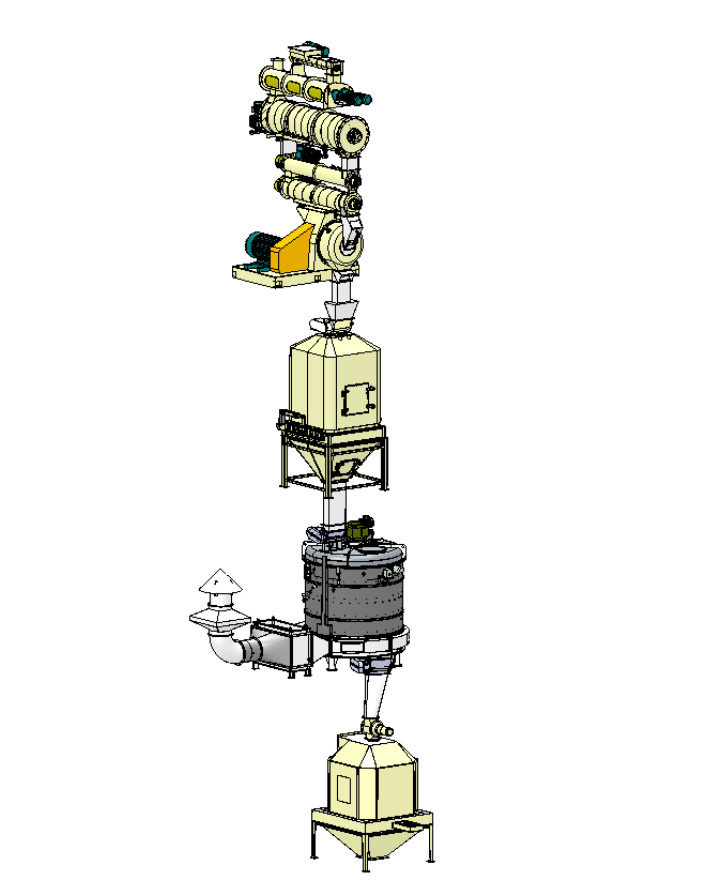

Figure 1. Carousel dryer model T-225-4

Figure 2. Pre-conditioner and pellet mill in the shrimp feed pellet mill system

Integrating carousel dryer in shrimp feed pelleting system

During the last 10 years, developments in pellet mill design enable us

to pellet material with moisture up to 17%. This development leads to

another problem in the shrimp feed production, the existing pelleting

system of pellet mill, post conditioner, and cooler are unable to dry

the pellets to shelf stable moisture of 9-10%. In order to lower the

moisture content, we incorporate the carousel dryer in the pelleting

system. From the time period of 2012 until 2020, there has been more

than 30 sets of carousel dryer used in shrimp feed pelleting plants.

In many factories, steam heat exchanger is used as the heat source of

drying air. There are many types of the steam heat exchanger in the

market, one of the most popular is the finned-tube heat exchanger

(FTHE). The problem of using this kind of FTHE lies in the

accessibility in cleaning, especially when multiple layers is needed.

The new design incorporates maintenance door and spacing between every

layer of heating tube in order to ease the cleaning process.

Drying and cooling in shrimp feed pelleting

Drying is naturally a highly energy intensive process. Drying process

have an unavoidable constraint which is they must supply enough heat or

energy to provide the latent heat of evaporation to remove the vapor

(around 2000 kJ/kg for water). Many companies view dryer as the main

target in application of their energy conservation program because in

most cases dryers are operated inefficiently. One way to converse energy

is by reusing the exhaust air from the dryer and cooler.

By arranging a carousel cooler directly under a dryer, both components

can be connected to one another - without enlarging the installation

area and even within existing systems. The warm exhaust air taken from

the cooler section is first fed to a filter unit and then pushed back to

the dryer section as energy-reducing warm air.

The typical

exhaust air temperatures from a cooler are around 45-55 ° C. After the

exhaust air has been cleaned using a pocket filter, the energy-rich

process air that has been prepared in this way is not released into the

atmosphere, but the warm unit is fed into the dryer area. The saving

effect on the heat exchanger is obvious: depending on the climatic

conditions, between 15 and 20% of primary energy can be saved here.

Use of a carousel dryer in the production line of shrimp feed

The typical production process for shrimp feed in the Far East is shown below. The figure shows schematically the functional processes of a pelletizing system, which comprises five individual components.

- Pre-conditioning system: this is where all the pre-cooking of raw material is done. In this system, heat is provided by both directly and in-directly injecting steam.

- Pellet forming system: specially designed pellet die and roller shell with the right compression ratio is set to produce a compact and tough pellet with higher PDI shrimp feed

- Post-conditioning system: this post conditioning is designed to prolong pellet cooking by providing hot temperature in order to avoid condensation.

- Drying system: dryer is incorporated in this system in order to lower the moisture to around 11%.

- Cooling system: Cooler will ensure the material is cooled to +/- 3 degrees from ambient temperature, in order to avoid condensation of pellets in the packaging.

Figure 3. Process flow of pellet mill and post-conditioning system

Figure 4. Carousel dryer model T-225-4 in customer site

Carousel dryer model T-225-4 in the shrimp feed line

One of our customer in Vietnam is using the carousel dryer model T225-4 for their shrimp feed production. This dryer has 2250 mm diameter with 4 decks of rotating drying trays (Screen tray perforation is 1.2 mm round shaped). The pellets produced varies from 1.2 mm to 2.0 mm. The pellets entered the dryer at 17 % moisture and leaving the dryer at around 11% moisture. Drying temperature inside the drying chamber is kept at around 75°C. This dryer is able to dry around 4 TPH (using 2.0 mm pellet die).