Blog and Article \ 2022 . 07 . 21

Drying and Cooling shrimp feed in One machine

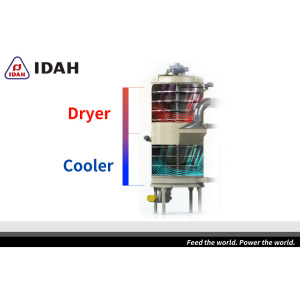

So what is the latest technology in drying and cooling shrimp feed? We considered all the requirements and the experience in the field and have developed a Generation 3 (G3) pelleting system that incorporates the dryer and cooler (TK-series) in one machine

READ MORE

Blog and Article \ 2022 . 06 . 24

Drying and Cooling of Bakery Grist at Its Finest with Carousel Dryer-Cooler (Published in dei-Germany).

Drying of bulk material can be a tricky and interesting process, simply because of the volume and number of material is larger. In order to provide an optimal drying process, it is important to understand the nature of the material to be dried. Some material may require gentle mechanical and thermal handling.

One example of the material is bakery grist (blend of wheat or grains). This is a pre-processed dough-like-mass consist of coarsely ground cereals, intended for baking whole-meal bread. When entering the dryer, it is quite pasty and sticky. The dryer-cooler (figure 1) is expected to lower the moisture down to around 10%. The drying temperature must not exceed 50°C in order to preserve the nutritive value.

READ MORE

Blog and Article \ 2022 . 06 . 17

Ingredient Contribution in Extruded Product - Carbohydrate Sources

During extrusion, there will be some changes in physical, chemical, functional, and nutritional properties.

Denaturation of protein is the most important attribute in changing the extrudate properties. According to Camire in Riaz (2000), protein changes during extrusion can be divided into functional and nutritional changes. Functionally, extrusion will reduce the solubility in water and diluted buffer also helps in texture forming of the extrudate. While nutritionally, extrusion will reduce lysine and improved digestibility.

READ MORE

Blog and Article \ 2022 . 05 . 20

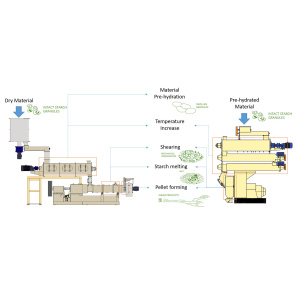

Optimal Pre-conditioning for Animal Feed

With the projection of a CAGR of 3-4% growth for the next 5 years (2022-2027), animal feed is a profitable business. IDAH understands this opportunity, and we support our customers by providing a high-quality pre-conditioner system for animal feed production.

READ MORE

Blog and Article \ 2022 . 03 . 17

Ingredient Contribution in Extruded Product - Protein Sources

During extrusion, there will be some changes in physical, chemical, functional, and nutritional properties.

Denaturation of protein is the most important attribute in changing the extrudate properties. According to Camire in Riaz (2000), protein changes during extrusion can be divided into functional and nutritional changes. Functionally, extrusion will reduce the solubility in water and diluted buffer also helps in texture forming of the extrudate. While nutritionally, extrusion will reduce lysine and improved digestibility.

READ MORE

Blog and Article \ 2021 . 12 . 16

Which is correct? Starch Cooking vs Starch Gelatinization

What comes to your mind when you heard “starch gelatinization”? If you are working in the food or feed business, I believe you have ever heard this at least once. But have you ever heard of “starch cooking?

READ MORE

Blog and Article \ 2021 . 12 . 01

Plant-based meat production by twin-screw extrusion (Video)

TVP technology has long been developed in Taiwan. With the increasing demand for a sustainable plant-based protein source, the development of a flexible but stable meat substitute production for the vegan population process has become a necessity. Our Twin Screw Extruder is designed with exact temperature control and adjustable screw to reform and re-structure the plant-based protein to generate protein fibers (fibration). This cooking extrusion process is important for the texture and mouthfeel of TVP and HMMA.

READ MORE

Blog and Article \ 2021 . 11 . 18

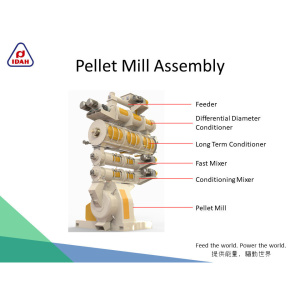

Pelleting process for high-quality shrimp feed (Video)

The production of high-quality shrimp (or prawn) feed is a series of complex and versatile processes. Shrimp feed pelleting is well known in Asia as the most economical way and it dominates the market. In China and India, the shrimp feed (for L. vannamei and P. monodon) market grew exponentially in these few years. Through this presentation, IDAH will guide you to the world of shrimp feed pelleting. In general making shrimp feed is influenced by good formulation and good processing, but the factory floorplan is also accountable for the shrimp feed quality.

READ MORE

Blog and Article \ 2021 . 09 . 16

Carousel Dryer - Reliable and Easy Moisture Control (Video)

Carousel Dryer - Reliable and Easy Moisture Control (Video)

Have total control over your dryer investment and energy consumption in your plant!

IDAH considers all of your process requirements FIFO system, moisture uniformity, efficient energy transfer, and easy operation to provide the suitable Carousel Dryer for your industry.

READ MORE

Blog and Article \ 2021 . 07 . 30

Complete system for shrimp feed pelleting

Choosing the right equipment is the first step for the success of the production process. Idah PM-series pellet mill which include PM-42, PM-51, PM-53 and PM-635 has been produced since 1980. These pellet mills have become the trademark in shrimp feed pelleting ever since.

READ MORE

Blog and Article \ 2021 . 07 . 29

Rotary Sifter for Efficient Material Classification

Rotary Sifter for Efficient Material Classification

This machine is operated by a belt pulley-driven wheel which generates eccentric circulatory movement, separating material in spiral and oscillating motion. This machine is suspended in the midair by steel cables, this design generates a controlled and specific motion trajectory. All these designs are proven to help effective material classification.

READ MORE

Blog and Article \ 2021 . 06 . 01

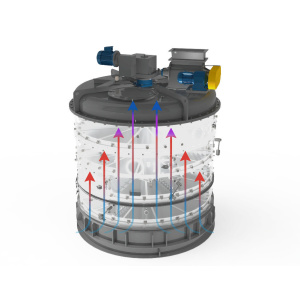

The Carousel Dryer - 30 years proven technology

For the past 40 years, IDAH designs and manufactures equipment and process lines for the aquafeed and pet food industries. In 2011, IDAH started focusing on the Carousel Dryer technology. Our team of expert Engineers has worked intensively to improve the Carousel Dryer technology even further to increase the drying process efficiency. The Carousel Dryer delivers outstanding performances when compared to traditional dryers. The main advantages of choosing a Carousel Dryer are:

• All the products undergo the same drying conditions, resulting in very uniform and steady drying.

• Optimal counter-flow heat transfer, resulting in low energy costs.

• Quick changeovers in a controlled way, lessen product contamination.

READ MORE