The Carousel Dryer - 30 years proven technology

This article is published in International Aquafeed June 2021

A proven technology with more than 30 years of history in the market

As there are a lot of dryer options available in the market. What

criteria are important for you to consider before making your selection?

If you are considering buying a new dryer and are looking for a dryer

with high reliability, easy moisture control, high energy efficiency,

and quick product changeover, then this article is definitely for you.

There are many different options, but this article will focus on the

CAROUSEL DRYER, proven technology with more than 30 years history in the

market.

The main function of a dryer is evaporating water. The evaporation must

uniformly take place and consistent in time, with minimum energy usage

and with the option for quick changeovers to minimize downtime and to

improve your overall drying process efficiency.

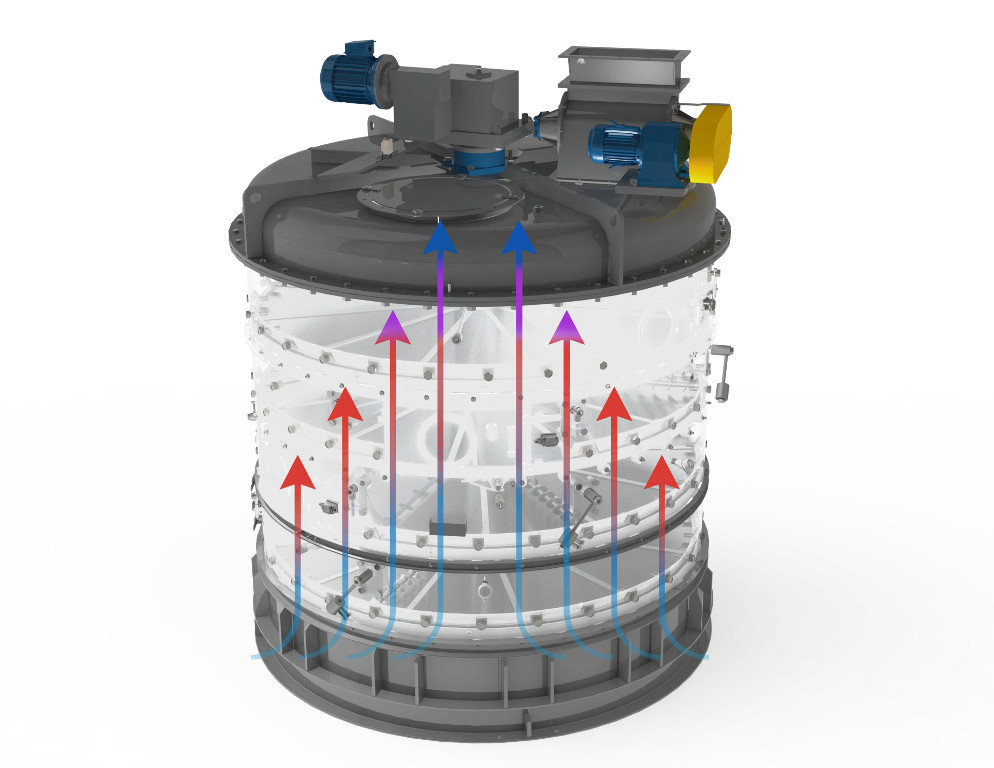

Figure 1. Airflow of carousel dryer

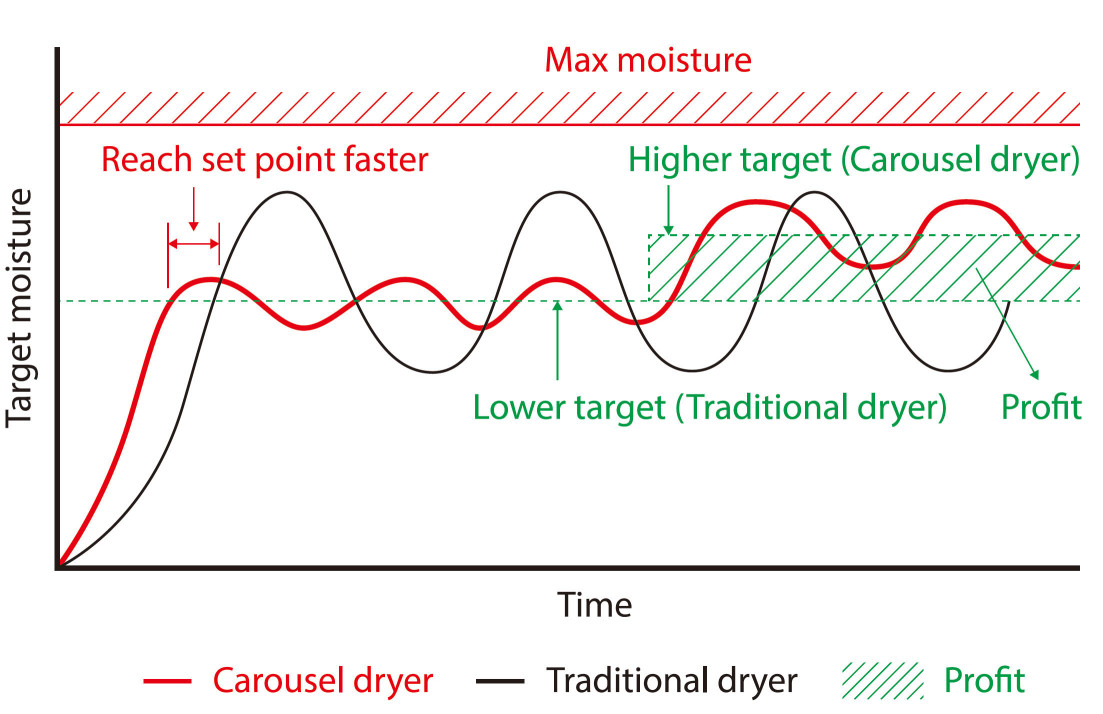

Figure 2. Target moisture changes in time

Reliable and Easy Moisture control

For the past 40 years, IDAH designs and manufactures equipment and

process lines for the aquafeed and pet food industries. In 2011, IDAH

started focusing on the Carousel Dryer technology. Our team of expert

Engineers have worked intensively to improve the Carousel Dryer

technology even further to increase the drying process efficiency. The

Carousel Dryer delivers outstanding performances when compared to

traditional dryers. The main advantages of choosing a Carousel Dryer

are:

• All the products undergo the same drying

conditions, resulting in very uniform and steady drying.

•

Optimal counter-flow heat transfer, resulting in low energy costs.

• Quick changeovers in a controlled way, lessen product

contamination.

The impact of moisture on your product

When choosing the correct dryer for your application, moisture control

should be one of the most important selection criteria. Moisture has

serious impact on your product quality and cost price levels, and

profits for your business One aspect of moisture control is uniformity,

together with drying result consistency–in-time will determine the

target average moisture content. The closer the average moisture to the

maximum moisture levels, then the less raw material are lost through

over-drying, generating more profit for your company.

In the cylindrical-shaped Carousel Dryer, the product is rotated 360° on

multiple decks and mixed by each drop when the tray gently tilts and the

material flows into the deck below. By rotating the product, the product

is situated in a fixed air stream, so all the product gets the same

drying conditions resulting in a product with uniform moisture and

consistent quality. In summary, uniform consistent drying is using less

raw material and reducing energy costs.

Improving dryer efficiency and saving energy costs

Water evaporation, or drying, is naturally a highly energy-intensive

process. The drying process has an unavoidable constraint to supply

enough energy for evaporation. The efficiency of a dryer will be

determined by the energy input about the amount of water evaporation.

The Carousel drying air passes the incoming product in this

multiple layer dryer in a counterflow direction to achieve maximum

heat transfer, resulting in a low exhaust air temperature. This in

combination with drying air recirculation will reduce the exhaust air

volume and improve energy efficiency.

Another option for energy conservation is the re-use of the cooling

air. Using the cooling air as make-up air for the dryer will reduce

the volume of exhaust air resulting in fewer odor control issues.

Plus, all the heat from the cooled product will be used in the dryer

for water evaporation. This combination will improve dryer efficiency

and saving energy costs.

The feed market trend is demanding to customize products, which

results in an increase of formula-changing frequency. This situation

demands producer to have a good and tight production schedule to keep

machine running optimally, while at the same time ensure no product

contamination using the FIFO (first in first out) principle.

Figure 4. Carousel dryer (Model TT-300-4-4) in customer site

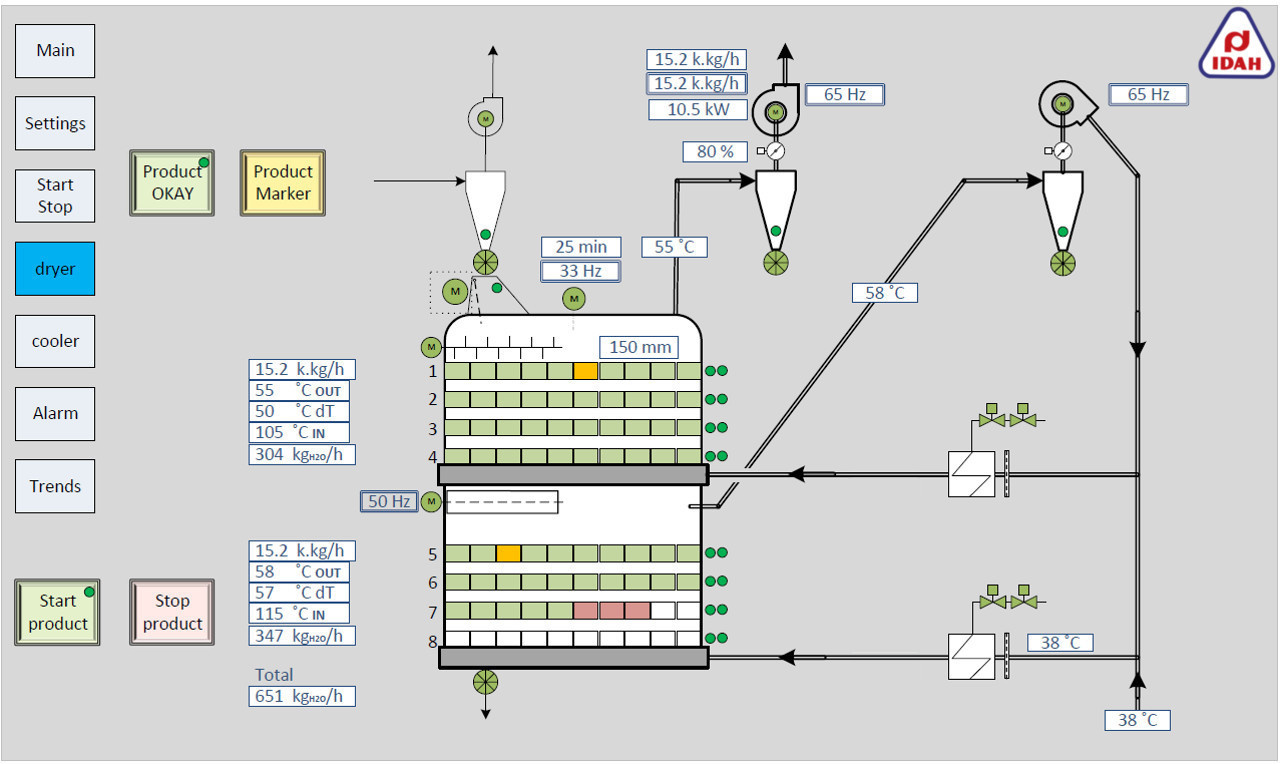

Figure 4. Control system for carousel dryer developed by IDAH

Developing an operator-friendly control system

In 2020, IDAH incorporated a new moisture control system. This control

the system consists of:

Air volume and Temperature control - The

control philosophy of the dryer will be a crucial factor in the overall

performance. To get maximum profit for the uniform drying performance of

the Carousel Dryer, we control the energy absorption from the product by

controlling the air volume and temperature control.

Water evaporation calculations - the Carousel Drying System helps

companies accurately control their product moisture and keep track of

any changes in the parameters during production. This will help the

operator to achieve and maintain the target moisture quickly and

efficiently.

Energy efficiency indication - With the automatic

calculation, the operator can see the efficiency of the drying process

and take quick measures whenever the numbers are abnormal. Energy

control is drying control

Total control over energy consumption in your plant

Depending on your expectation of an ideal dryer, you may have to look

for different dryer options in the market. The dryer is a big investment

and also a big energy consumer in your plant.

IDAH considers all

of your process requirements, moisture uniformity, efficient energy

transfer, easy operation, and minimal down-time to select the suitable

Carousel Dryer for your industry.