IDAH participated in Victam Asia 2024 in Bangkok

Our team had a great week at Victam Asia 2024. Thank you to everyone who visited our booth to experience the all-new TwinTech Extruder, Pellet Mill 7900 and other solutions for the animal feed, aquafeed and pet food markets.

READ MORE

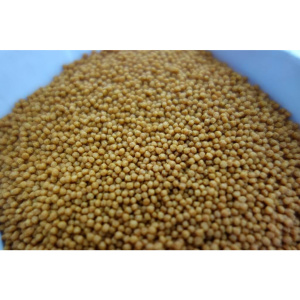

Ingredient Contribution in Extruded Product - Carbohydrate Sources

During extrusion, there will be some changes in physical, chemical, functional, and nutritional properties.

Denaturation of protein is the most important attribute in changing the extrudate properties. According to Camire in Riaz (2000), protein changes during extrusion can be divided into functional and nutritional changes. Functionally, extrusion will reduce the solubility in water and diluted buffer also helps in texture forming of the extrudate. While nutritionally, extrusion will reduce lysine and improved digestibility.

READ MORE

IDAH is your reliable partner.

Customer satisfaction is IDAH’s ultimate goal. Even in these times of uncertainty, IDAH continues to provide machines, services, and spare parts to our customers all over the world.

IDAH offers high-quality dryer, pelleting, and extruder machines.

Pellet dies from IDAH are made from high-quality Europe ring die, with precise machining, ensuring longer use life.

READ MORE

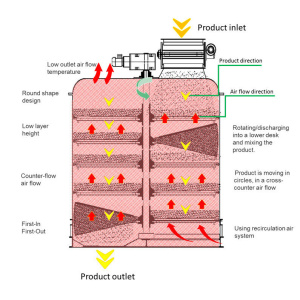

Carousel Dryer and Cooler for Food

Besides energy consumption, the drying process will change the color, texture, odor, and other properties of solid products. Hence it is of the utmost importance for a dryer to dry effectively with low energy consumption.

The carousel dryer is developed to dry the food with small space requirement, quick product change, lower energy requirement, lower air volume requirement, gentle tumbling across the drying deck, and uniform moisture.

READ MORE

Ingredient Contribution in Extruded Product - Protein Sources

During extrusion, there will be some changes in physical, chemical, functional, and nutritional properties.

Denaturation of protein is the most important attribute in changing the extrudate properties. According to Camire in Riaz (2000), protein changes during extrusion can be divided into functional and nutritional changes. Functionally, extrusion will reduce the solubility in water and diluted buffer also helps in texture forming of the extrudate. While nutritionally, extrusion will reduce lysine and improved digestibility.

READ MORE

Customer

The top 10 leading feed companies in Asia all rely on IDAH’s innovative technologies. /

Not only in East Asia, but the IDAH network has also grown to South East Asia, Europe, Middle East, Africa, and Latin America. Almost 80% of our sales come from the testimony and recommendation of our customer, we let the quality of our machines speak for itself.

Join them by entrusting IDAH as your machine and solution provider.

READ MORE

About Us

Not only in East Asia, but the IDAH network has also grown to South East Asia, Europe, the Middle East, Africa, and Latin America. /

Almost 80% of our sales come from the testimony and recommendation of our customer, we let the quality of our machines speak for itself.

To ensure high service quality, we actively collaborate with local representatives and agents. Active communications and training are provided for these representatives and agents to provide premium and professional service for our customers.

READ MORE

Maintenance

IDAH has 5 offices plus 10 plus agents worldwide. We provide support when our customers facing problems or troubles. Please call us or contact us via the internet, our experienced engineers will work with you to solve the problem, or our nearest engineer can visit the site to offer onsite consultation or technical supervision.

READ MORE

Spirit and Vision

Creativity is what gave birth to IDAH in 1974 and consequently the birth of the feeds manufacturing industry in Asia. / Innovation through creativity is what has enabled us to be the industry driver from our inception until now. IDAH is committed and well-positioned to lead the industry of tomorrow. If creativity is the engine that has rapidly pushed IDAH forward; Honesty is what keeps us moving in the right direction. IDAH has been firmly grounded on the virtues of quality, honor, and accountability. Our main business is to safeguard the trust that customers have given us and be a dedicated upholder of the highest quality standard.

READ MORE

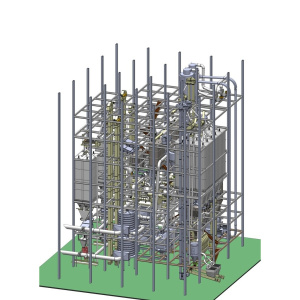

Turnkey Projects

IDAH has completed over 300 turnkey projects in 21 countries since 1974. We have enabled our customers to experience rapid growth by using our processing machines and complete plant solutions. These customers included the top 10 leading feed companies in Asia.

IDAH applied a 3D design program to simulate the process flow, to reduce the time and money needed while manufacturing machines, constructing machine towers, and machines installation. IDAH machinery and spare parts are produced with optimal design and conforming the accepted standards of safety and quality, providing premium quality and reliable products. Not only standard machinery, but IDAH also provides customizable machines for customers.

READ MORE

Dry Pet Food

Pet food is a growing market, the amount of demand increases almost every year. IDAH offers complete solution for pet food production from the material intake up until the packaging. Every machine is carefully and precisely manufactured to provide high quality machine for feed and food production.

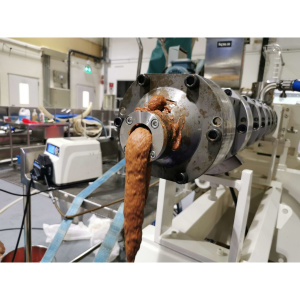

Idah has patented contra-twin shaft extruder which utilize a combination of steam and mechanical energy from the screw, generating lower SME during production. In Pet food system, IDAH incorporate the carousel dryer which able to precisely control temperature, producing uniform moisture with quick product change-over

READ MORE

Semi-moist Pet Food Treat

Pet food is a growing market, the amount of demand increases almost every year. IDAH offers a complete solution for pet food production from the material intake up until the packaging. Every machine is carefully and precisely manufactured to provide a high-quality machine for feed and food production.

Idah has a patented contra-twin shaft extruder that utilizes a combination of steam and mechanical energy from the screw, generating lower SME during production. In Pet food system, IDAH incorporate the carousel dryer which can precisely control temperature, producing uniform moisture with quick product change-over

READ MORE

Specialized Pet Food

Pet food is a growing market, the amount of demand increases almost every year. IDAH offers a complete solution for pet food production from the material intake up until the packaging. Every machine is carefully and precisely manufactured to provide a high-quality machine for feed and food production.

Idah has a patented contra-twin shaft extruder that utilizes a combination of steam and mechanical energy from the screw, generating lower SME during production. In Pet food system, IDAH incorporate the carousel dryer which can precisely control temperature, producing uniform moisture with quick product change-over

READ MORE

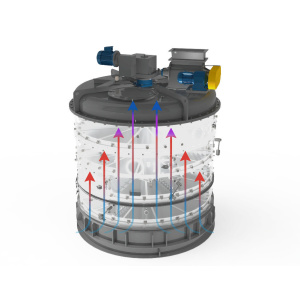

Mixing

IDAH started the technology transfer and manufacture of the twin paddle mixer in 1989. /

Until today, this technology constantly undergoes revolutionary breakthroughs in research and development, using scientific data to develop new techniques and technologies in manufacturing robust and tailored machinery for aqua feed, animal feed, wood pellet, and biomass industries.

READ MORE

Drying

What criteria are essential for you to consider before making your selection?/

There are a lot of dryer options available in the market. Are you looking for a dryer with high reliability, energy-efficient, easy moisture control, and quick product changeover? Then IDAH T-series and CDX-series dryer is the best selection for you.

READ MORE

Carousel Dryer for Pet Food Drying / Germany

An actual result that we obtain from the premier producer of commercial pet foods in Germany. IDAH carousel dryer has a round shape for uniform airflow and gentle drying process through tumbling of the dryer through multiple layers of rotating perforated screen segments design.

READ MORE

The Carousel Dryer - 30 years proven technology

For the past 40 years, IDAH designs and manufactures equipment and process lines for the aquafeed and pet food industries. In 2011, IDAH started focusing on the Carousel Dryer technology. Our team of expert Engineers has worked intensively to improve the Carousel Dryer technology even further to increase the drying process efficiency. The Carousel Dryer delivers outstanding performances when compared to traditional dryers. The main advantages of choosing a Carousel Dryer are:

• All the products undergo the same drying conditions, resulting in very uniform and steady drying.

• Optimal counter-flow heat transfer, resulting in low energy costs.

• Quick changeovers in a controlled way, lessen product contamination.

READ MORE

Extrusion for pet food production / Thailand

Another new innovation from IDAH. We are introducing the new ZPT85A Twin-screw extruder. This extruder is intended for pet food production in Thailand. This extruder is designed using stainless steel barrel with a self-cleaning intermeshing screw design. It is our honor to be part of this Company's development.

READ MORE

High Capacity Fish Feed Production with EP-218 Extruder / Indonesia

Model: EP-218

Machine: Single screw extruder

Motor: 400HP

Screw size: 218 mm

Capacity: 8~10 TPH floating feed (at 3.0 mm plate die size)

What separates our EP-218 single screw extruder from the other:

1. Automatic bearing lubrication system, with interlock to the main motor. Ensures bearing is lubricated throughout the operation

2. Loss-in-weight live bin for precise addition of steam and water in the pre-conditioner and extruder barrel.

3. The implementation of the latest venturi technology to provide the most suitable pressure needed in the extruder outlet.

READ MORE

Good Dryer Design For High Quality Aquafeed

Nowadays, in the fiercely competitive market environment, every miller uses a similar process as well as ingredients, therefore, the product quality and manufacture cost become the thread of the competition. Overview of the process, dryer performance plays a critical role in this game. For selecting a suitable dryer, two main issues need to be considered, first is average moisture control from dried products and the second is energy efficiency, both are related to the water!

READ MORE