Good Dryer Design For High Quality Aquafeed

This article is published in Aquafeed: Advances in Processing & Formulation Vol. 11 Issue 2 2019

Nowadays, in the fiercely competitive market environment, every miller

uses the similar process as well as ingredients, therefore, the

product quality and manufacture cost becomes the thread of the

competition. Overview of the process, dryer performance play a

critical role in this game. For selecting a suitable dryer, two main

issues need to be considered, first is average moisture control from

dried product and second is energy efficiency, both are related with

the water!

Moisture uniformity is one of the critical factors when

you judge dryer performance. In the feed production process, the

moisture uniformity is not only related to the product quality and

energy efficiency but also will impact your profitability directly.

Because products are sold by weight, a narrow moisture

tolerance will improve product quality and avoiding raw material loss.

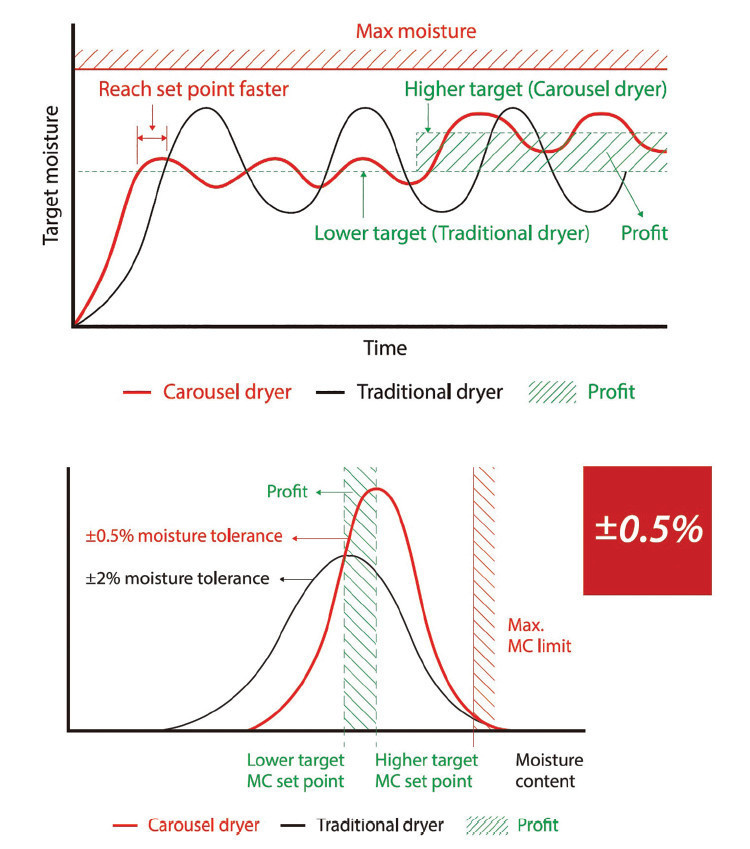

As shown in Figure 1, the black curve indicates the traditional dryer

and red curve for the advantage dryer such as the carousel dryer. A

narrow range of moisture tolerance allows the moisture setpoint to be

higher without the risk of exceeding the maximum moisture limit, the

profit is shown as a green zone. Suppose your final product maximum

moisture content is 10%, in carousel dryer, the moisture control

setpoint will be 9.5% rather than 8% in the traditional dryer. The

result is you get 1.5% more product and saving drying energy at the

same time. The value of these profits due to the moisture uniformity

in combination with accurate moisture control can be surprising.

For instance, imagine a feed mill that produces 100,000

tons of extruded aquafeeds per year with a maximum moisture content of

10 %. The product cost $200 per ton. If we compare a dryer with ± 0.5%

and another with ± 2.0%, there is 1.5% more product to be sold with

the same amount of raw ingredients. It is easy to calculate if you use

a carousel dryer saving estimate $300,000 /year (100,000*1.5%*$200).

In addition to the selling profits, a narrow moisture tolerance also

avoids the energy waste from the over-dry. For the 10 t/h capacity

extrusion line, for example, 1.5% less moisture evaporation will save

200 kg/hour steam consumption.

In the short conclusion,

with the carousel dryer, the product is handled with more stable

moisture control in-time, less over-drying (avoid product loss), and

with a higher average moisture content.

Figure 1. Moisture uniformity comparison between the carousel dryer and traditional dryer

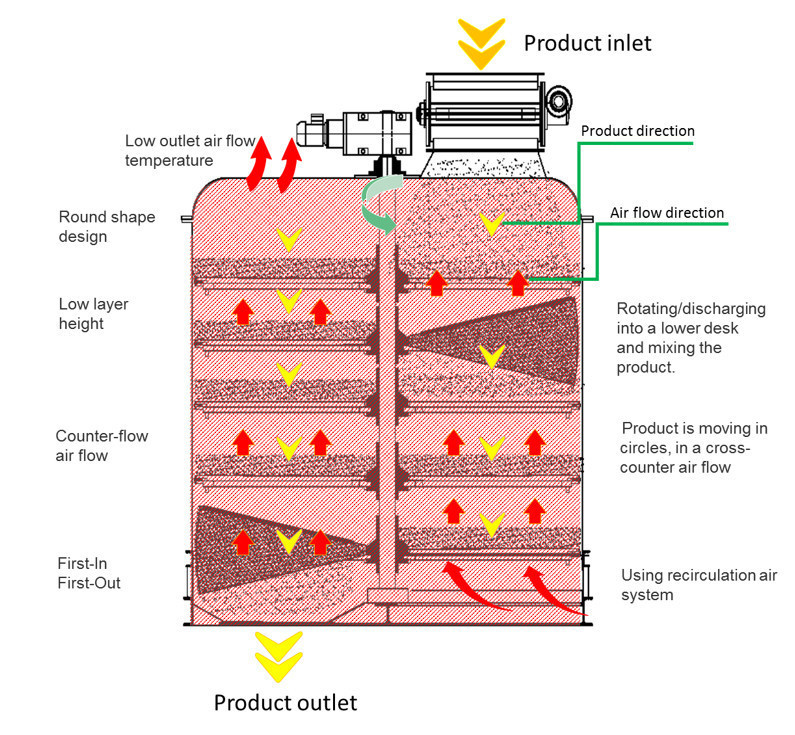

Figure 2. The characteristic of a carousel dryer design

Design requirements

What are the design requirements to achieve a dryer with ± 0.5% moisture tolerance?

- The product layer height need to be lower (normally less than 20cm). A high layer will cause un-even drying in which the bottom product gets more drying as air enters than the product on the top where air leaves.

- A round shape design in which optimize airflow distribution. Since it has no dead spots inside the dryer, also improves air distribution and hygiene as well.

- A counter-flow air stream, giving an optimized heat transfer goes through the perforated circular trays and product. The product is moving in circles, in a cross-counter airflow.

- The product in the dryer is rotating and discharging into a lower deck and tumble product for mixing. This will be done in each deck before the product is leaving the dryer with very uniform moisture, it also implies all the product gets the same treatment bypassing different air volume and temperatures.

- The product flow is First-in, First-out (FIFO). Every pellet is getting the same retention time that is similar to continuous production, the operator can easily identify the batch of product quality and correct it immediately if need be.

Energy efficiency

Another indicator for the dryer performance is energy efficiency, drying

is a very energy-intensive operation. When extrudate discharge from the

extruder, the moisture content can be 20-30%, the dryer energy is

significant and easily more than 50% of the plant’s energy consumption.

Thus, it is a very challenging task to optimize the drying process

efficiency without compromising the quality. The ultimate goal is

energy-saving and product quality improvement. Several studies in the

literature show how the drying inlet/outlet parameters impact energy

efficiency. In conclusion, the inlet, outlet process air temperature,

and air volume are three major factors to determine the amount of water

evaporation.

Basically, the value of air volume equal to drying surfaces

multiplies air velocity. The drying surface is fixed by a specific

design, the velocity is limited by the size and density of pellets,

therefore only the delta T is the flexible parameter for energy

efficiency. The rule of thumb for delta T is as following,

-

The airflow temperature that leaves the dryer need to be lower

The lower the outlet airflow temperature means the more air energy is used for water evaporation. -

The airflow temperature that enters the heater needs to be higher

The higher inlet air temperature meaning the airflow needs less heater energy to approach the setpoint temperature.

Good air system

Therefore, a good air system like a carousel dryer has the following characteristics and as shown in Figure 2.

-

Using the recirculation air system

Using the cooler air or dryer exhaust air as the make-up air. -

Independent heating zone

The desire air volume and delta T could be set in each specific zone. -

Counter-flow design

The definition of counter-flow in the dryer design is the material drop from up to down and the airflow motion is bottom-up, as some literature showed, the counter-flow design will be more than 10% better efficiency than a cross-flow dryer like a belt or horizontal dryer. -

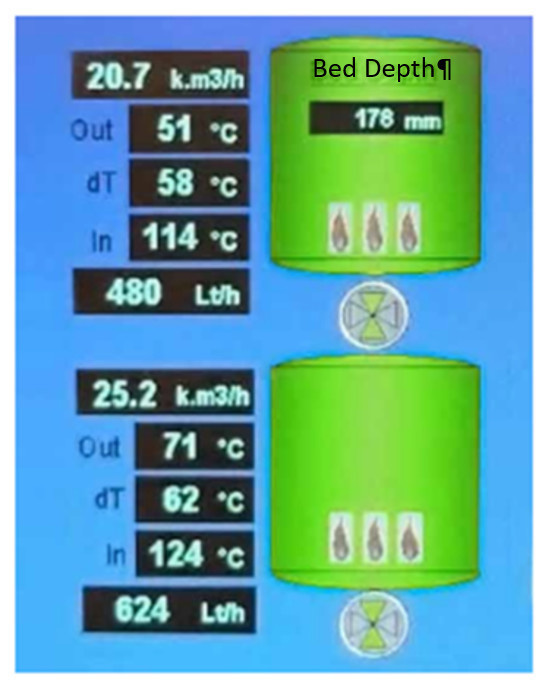

Easy control

Since the delta temperature, air volume and retention time all of the parameters will impact the dryer performance, this is necessary to design a simple rule that allows the operator easy to follow as shown in Figure 3. In the carousel dryer design, the operator only needs to verify the product outlet moisture, then adjust the inlet airflow temperature until approaching the target moisture. In practice, one percent moisture drop required 3℃ temperature raise.

Figure 3. A sample of individual heating sections with independent control.