IDAH Extrusion - Since 1980s

IDAH extruder history started in the 1980s. We begin our extrusion technology by designing and manufacturing the single screw extruder to produce floating and sinking fish feeds. At that moment, IDAH extruder was the only professional made-in-Asia aqua feed extruder for the Asia market. This progress rapidly opened the market, and IDAH extruders became very popular in Asia countries.

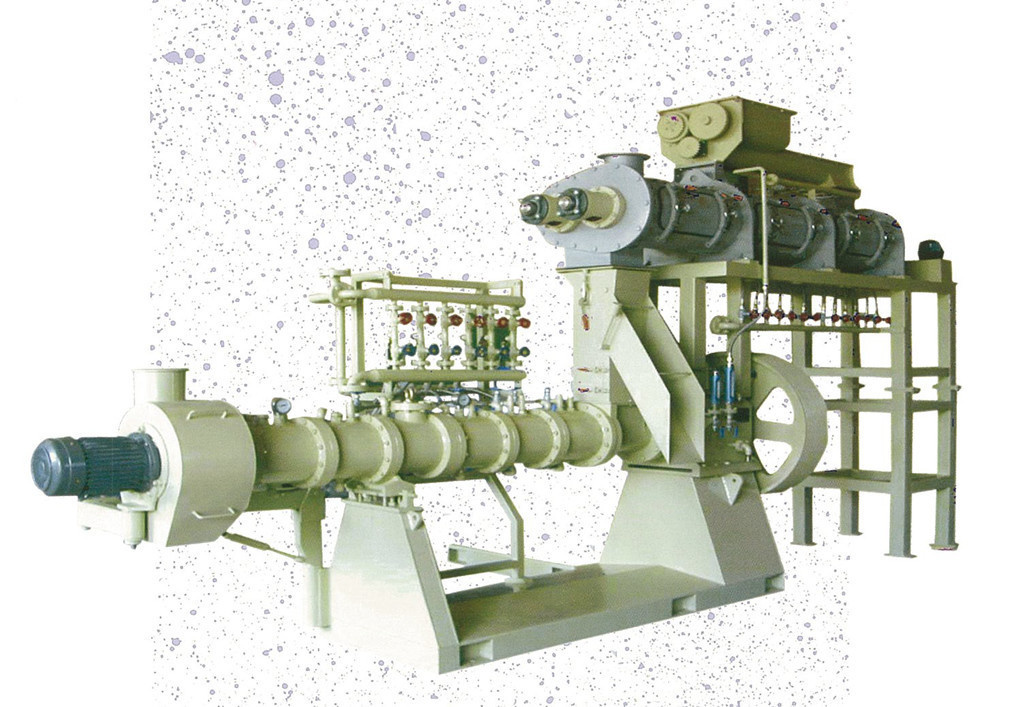

IDAH extruder EP-120 used in 1980s

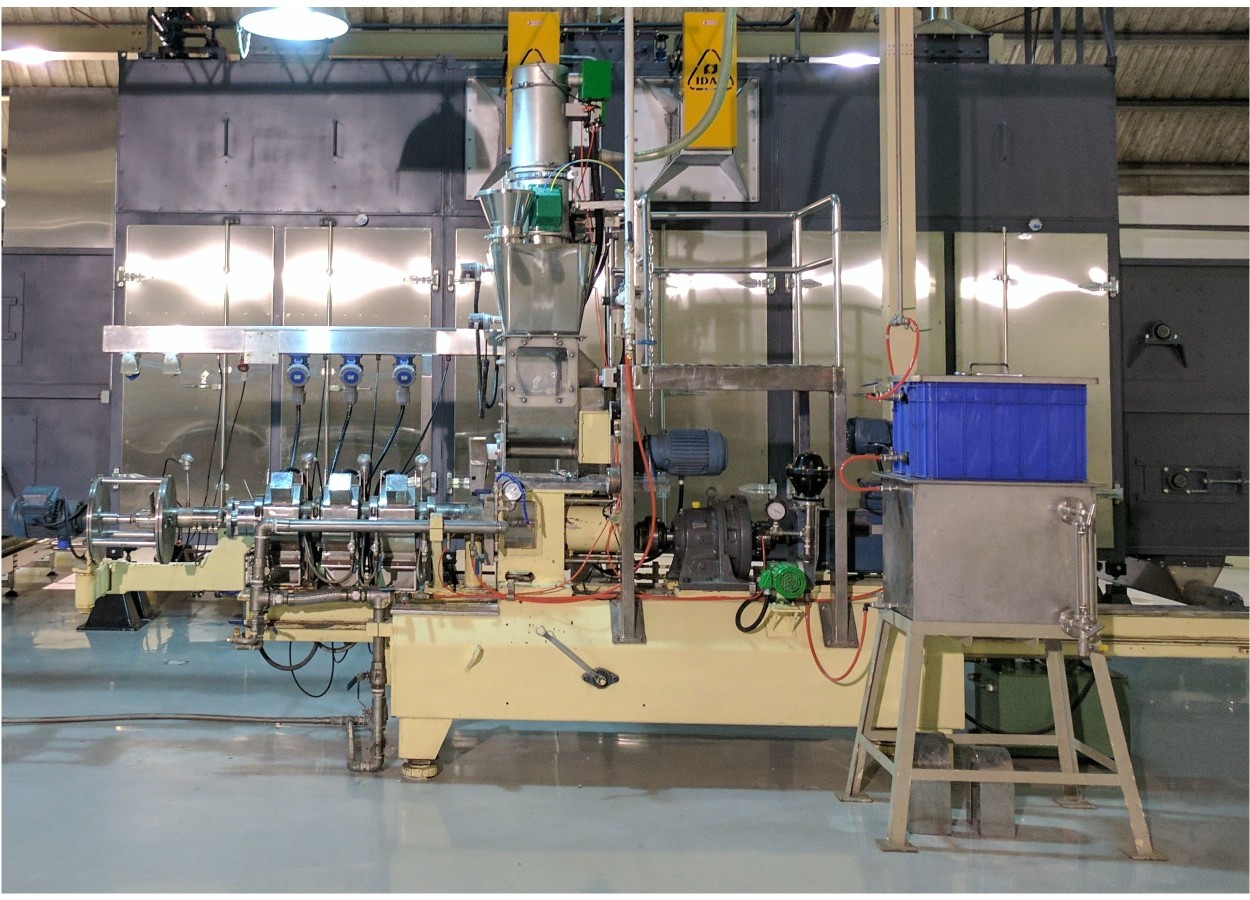

IDAH Innovation Center for Food and Feed

As time evolved, the IDAH extruder begins to expand its capabilities into other applications. In 1995, IDAH developed a co-rotating twin-screw extruder, a food-grade 55mm screw diameter model, for extruded food and pet food products. A year later, to increase the meat-alternative market know-how, we established the IDAH extrusion research center dedicated to textured-vegetable-protein (TVP) research. In 2015, the extrusion research center expanded to what we knew now as the IDAH Innovation Center.

Patented ContraTwin Extruder

After gaining much twin-screw extrusion experience in making food, IDAH proposed a novel twin-screw extrusion solution for considering the benefits of producing premium pet food and aqua feed, later as we call the technology: ContraTwin. Later on, we acquired the patent for ContraTwin screw extrusion in the US, Taiwan, and China.

Extruder for High-Quality Cooking

The screw design can uniformly pressurize the raw material to generate uniform expansion to develop a crunchy texture in pet food. The friction of the screw and liner inside the barrel can perform high-temperature short time cooking for the grains material.

Maintenance and Repair

We understand that maintenance is also one of the substantial aspects of choosing a machine. IDAH extruders are made from high-quality metal with an advanced manufacturing process to ensure the durability of the extruder. Continuous lubrication of the bearing house and gearbox are direct-linked to the main power as a safety precaution. The lubrication system minimizes the downtime caused by the gearbox and bearing house failure.

Our Value

The value we bring to our customers maintains our position in the feed and food machinery market. Apart from marketing many extruders worldwide, our IDAH Innovation Center, which focused on research for extruded food, extruded aqua feed, and pet food, can give us more insights into the technology and discover more products and formulation potential. In this research center, we can experience the problems that our customers are experiencing during production, which also helps us continuously improve our extrusion technology.

Controls the density of sinking aquafeed

The Density Control Unit is additional device for extruder line production for producing sinking feed, slow-sinking feed and density-controlled extrusion product.

DCU comprised of airtight knife housing and airlock. The knife housing is paired with the airtight plate die to form closed environment. The airlock is fixed with a clamp to the knife housing.

The controlled pressure is able to:

- Control the water boiling point, ensure less flash-off, prevent expansion, and increase pellet density.

- Increase density of extruded pellets, increase feeding rate, thus increase the capacity.

Features

- Airtight design, no air leak

- Easy pressure control, stable density

- Pneumatic valve design, easy airlock disassembly

- Equipped wih safety valve

- Stainless steel for surface in contact with material

Benefits

- Increase capacity for sink feed production more than 15%

- Lower moisture in outlet 2-3%, lower the need of drying

- Smoother pellet surface

- Eliminate the need of oil to control density

- Slow and fast sinking made possible

- Customizable for different types of extruder