Ingredient Contribution in Extruded Product - Carbohydrate Sources

During extrusion, there will be some changes in physical, chemical, functional, and nutritional properties.

Denaturation of protein is the most important attribute in changing the extrudate properties. According to Camire in Riaz (2000), protein changes during extrusion can be divided into functional and nutritional changes. Functionally, extrusion will reduce the solubility in water and diluted buffer also helps in texture forming of the extrudate. While nutritionally, extrusion will reduce lysine and improved digestibility.

READ MORE

Ingredient Contribution in Extruded Product - Protein Sources

During extrusion, there will be some changes in physical, chemical, functional, and nutritional properties.

Denaturation of protein is the most important attribute in changing the extrudate properties. According to Camire in Riaz (2000), protein changes during extrusion can be divided into functional and nutritional changes. Functionally, extrusion will reduce the solubility in water and diluted buffer also helps in texture forming of the extrudate. While nutritionally, extrusion will reduce lysine and improved digestibility.

READ MORE

We are ready for commissioning in Egypt

We are ready for the commissioning of the floating fish feed plant in Egypt.

With the support of our customer and representative in Egypt, we have finished the installation of this feed extrusion plant with main machines including vertical pulverizer ZP-150, ContraTwin extruder EP-156DF, horizontal dryer CD-2508H, and rotary drum coater MR-1004.

READ MORE

Which is correct? Starch Cooking vs Starch Gelatinization

What comes to your mind when you heard “starch gelatinization”? If you are working in the food or feed business, I believe you have ever heard this at least once. But have you ever heard of “starch cooking?

READ MORE

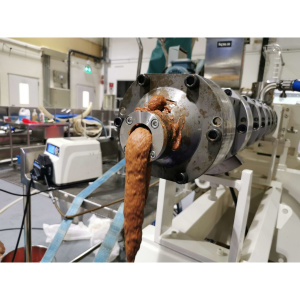

Plant-based meat production by twin-screw extrusion (Video)

TVP technology has long been developed in Taiwan. With the increasing demand for a sustainable plant-based protein source, the development of a flexible but stable meat substitute production for the vegan population process has become a necessity. Our Twin Screw Extruder is designed with exact temperature control and adjustable screw to reform and re-structure the plant-based protein to generate protein fibers (fibration). This cooking extrusion process is important for the texture and mouthfeel of TVP and HMMA.

READ MORE

Spare Parts

High-quality spare parts are essential to maintain equipment at its prime performance. IDAH understands customers have strong demands for wear parts that attain on-time delivery and supreme quality. IDAH takes relentless efforts to develop new material systems for all wear parts for a longer life span and installs modern production systems to support on-time delivery. All the efforts will result to give customers minimized downtime and product costs.

READ MORE

Fish Feed

In order to support provide a balanced and stable feeding for the farmed fish, many producers have shifted to manufactured pellets. Based on the behaviour in the water, fish feed can be divided into floating feed, slow-sinking feed, and sinking feed. IDAH offers you extrusion and pellet mill to produce high quality fish feed.

READ MORE

Technical Support

Making profitable feed or food cannot be determined by how single machinery performs. Moreover, we need to consider the adequate process flow, local-based formulation design, and plant management that covers quality assurance, equipment operations, and maintenance. IDAH expert teams help to provide technical support for your industry.

READ MORE

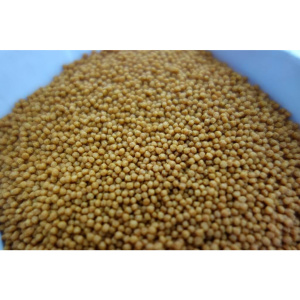

Texturized vegetable Protein (TVP)

Since the 1980s’, Taiwan has used soybean and wheat as two base materials to develop textured vegetable protein (TVP) technology. The textured vegetable protein has a meat-like texture and can be made into various healthy vegetarian food products.

Based on decades of experience in operating a vegetarian food company, IDAH has complete know-how in converting textured vegetable protein (TVP) into different plant-based meat (vegetarian meat).

READ MORE

Dry Pet Food

Pet food is a growing market, the amount of demand increases almost every year. IDAH offers complete solution for pet food production from the material intake up until the packaging. Every machine is carefully and precisely manufactured to provide high quality machine for feed and food production.

Idah has patented contra-twin shaft extruder which utilize a combination of steam and mechanical energy from the screw, generating lower SME during production. In Pet food system, IDAH incorporate the carousel dryer which able to precisely control temperature, producing uniform moisture with quick product change-over

READ MORE

Semi-moist Pet Food Treat

Pet food is a growing market, the amount of demand increases almost every year. IDAH offers a complete solution for pet food production from the material intake up until the packaging. Every machine is carefully and precisely manufactured to provide a high-quality machine for feed and food production.

Idah has a patented contra-twin shaft extruder that utilizes a combination of steam and mechanical energy from the screw, generating lower SME during production. In Pet food system, IDAH incorporate the carousel dryer which can precisely control temperature, producing uniform moisture with quick product change-over

READ MORE

Specialized Pet Food

Pet food is a growing market, the amount of demand increases almost every year. IDAH offers a complete solution for pet food production from the material intake up until the packaging. Every machine is carefully and precisely manufactured to provide a high-quality machine for feed and food production.

Idah has a patented contra-twin shaft extruder that utilizes a combination of steam and mechanical energy from the screw, generating lower SME during production. In Pet food system, IDAH incorporate the carousel dryer which can precisely control temperature, producing uniform moisture with quick product change-over

READ MORE

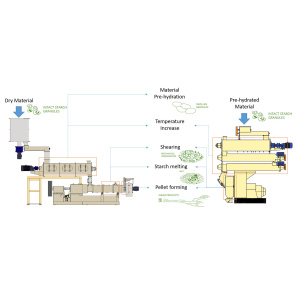

Extrusion

Today, IDAH offers the single screw extruder, co-rotating twin-screw extruder, contra-rotating twin-screw extruder (Pat.), and grain expander. /

We utilize the profile of screw and liner, direct steam injection into the extrusion barrel, and heating/cooling jacket to generate the most suitable cooking of the raw material. In aqua feed and pet food production, the addition of a pre-conditioning system can help increase the pre-cooking and hydrating process to manufacture premium feed with high water stability.

READ MORE

High Moisture Meat Analogue

Since the 1980s’, Taiwan has used soybean and wheat as two base materials to develop textured vegetable protein (TVP) technology. The textured vegetable protein has a meat-like texture and can be made into various healthy vegetarian food products. Based on decades of experience in operating a vegetarian food company, IDAH has complete know-how in converting textured vegetable protein (TVP) into different plant-based meat (vegetarian meat).

READ MORE

Extruder start-up waste can be reused!

Extruder start-up waste can be reused!

The BN-50H dryer is operated with a 3.7 kW drive motor. With two feeding doors, one exhaust pipe, and a manual slide gate. Steam-jacket the heater will help to dry 200-250 kg per batch of extrusion start-up material down to 10-12%. This machine opens up a new possibility to re-cycle the start-up material.

Our customer in Indonesia recently bought this dryer to complete their existing extrusion system. Extrusion has been an important step in production. IDAH has been providing a complete solution for feed and food extrusion since the 1980s. One of the important auxiliary machines in demand is this dryer for extrusion start-up waste (Model BN-50H)

READ MORE

Extrusion for pet food production / Thailand

Another new innovation from IDAH. We are introducing the new ZPT85A Twin-screw extruder. This extruder is intended for pet food production in Thailand. This extruder is designed using stainless steel barrel with a self-cleaning intermeshing screw design. It is our honor to be part of this Company's development.

READ MORE

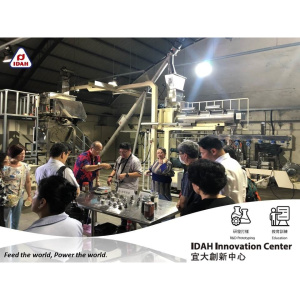

IDAH welcome Innovation Center Visitor in October 2020

IDAH welcome Innovation Center Visitor in October 2020

At IDAH, we understand that innovation grows from collective wisdom and experience.

IDAH’s Innovation Center, an extrusion research lab, fosters an environment of innovation through open experimentation: providing direct hands-on access to industry and machinery. We can develop a competitive and innovative product with you.

READ MORE

400HP single screw extruder

What separates our EP-218 single screw extruder from the other:

Automatic bearing lubrication system, with interlock to the main motor. Ensures bearing is lubricated throughout the operation

Loss-in-weight live bin for precise addition of steam and water in the pre-conditioner and extruder barrel.

The implementation of the latest venturi technology to provide the most suitable pressure needed in the extruder outlet.

READ MORE

High Capacity Fish Feed Production with EP-218 Extruder / Indonesia

Model: EP-218

Machine: Single screw extruder

Motor: 400HP

Screw size: 218 mm

Capacity: 8~10 TPH floating feed (at 3.0 mm plate die size)

What separates our EP-218 single screw extruder from the other:

1. Automatic bearing lubrication system, with interlock to the main motor. Ensures bearing is lubricated throughout the operation

2. Loss-in-weight live bin for precise addition of steam and water in the pre-conditioner and extruder barrel.

3. The implementation of the latest venturi technology to provide the most suitable pressure needed in the extruder outlet.

READ MORE