IDAH has developed numerous ready-to-sell textured vegetable protein (TVP), or specifically textured soy protein from soy isolate powder. We have complete know-how from formulation and processing equipment.

| Item | Texturized Vegetable Protein (TVP) |

| Characteristic | Low moisture extrusion |

| Moisture in extruder outlet (%wb) | 17-23 |

| Moisture in dryer outlet (%wb) | 7-9 |

| Texture | The expanded, fibrous, spongy texture |

Raw material

The raw material consists of high protein powdery material

Dry mixing

In this step, trace ingredients such as vitamins and minerals will be added and mixed

Extrusion

During extrusion, the material will undergo high pressure, high

temperature, and shearing in the barrel.

This treatment will induce the formation of protein fiber.

Drying

Drying in TVP is an optional process, some TVP will be frozen and

distributed in wet form.

When dried, wet TVP will enter the dryer and come out as dried

TVP with long shelf life.

Cooling

Cooling utilizes ambient air to cool down the hot product coming out

from the dryer.

Thorough cooling is needed to prevent condensation inside the

packaging.

Packing

Packing gives protection to the products also gives easiness to handle and transport to customer's hand.

Manufacturing Process of TVP

Features and Benefits of IDAH Process Design and Equipment

Since the 1980s’, Taiwan has used soybean and wheat as two base materials to develop textured vegetable protein (TVP) technology. The textured vegetable protein has a meat-like texture and can be made into various healthy vegetarian food products. Based on decades of experience in operating a vegetarian food company, IDAH has complete know-how in converting textured vegetable protein (TVP) into different plant-based meat (vegetarian meat).

IDAH has established a food laboratory since the 1990s, specializing in TSP (Soy Extruded Protein) and IWP (Soy Protein Isolate), and successfully developed plant-based meat (vegetarian meat).

The laboratory was upgraded to a food research factory and began to produce various vegetarian products.

Technical cooperation with the Food Industry Research Development Institute of Taiwan, and the Food Research Institute of Taiwan Ocean University, successfully exported vegetarian meat to the United States.

The food plant of vegetarian meat products was sold to Taiwan Top 5 food company in Taiwan.

IDAH Innovation Center was established to continue to research and develop plant-based meat, becoming the first and only base in Taiwan to provide vegetarian meat equipment, proofing and testing, education and training, and food research and development.

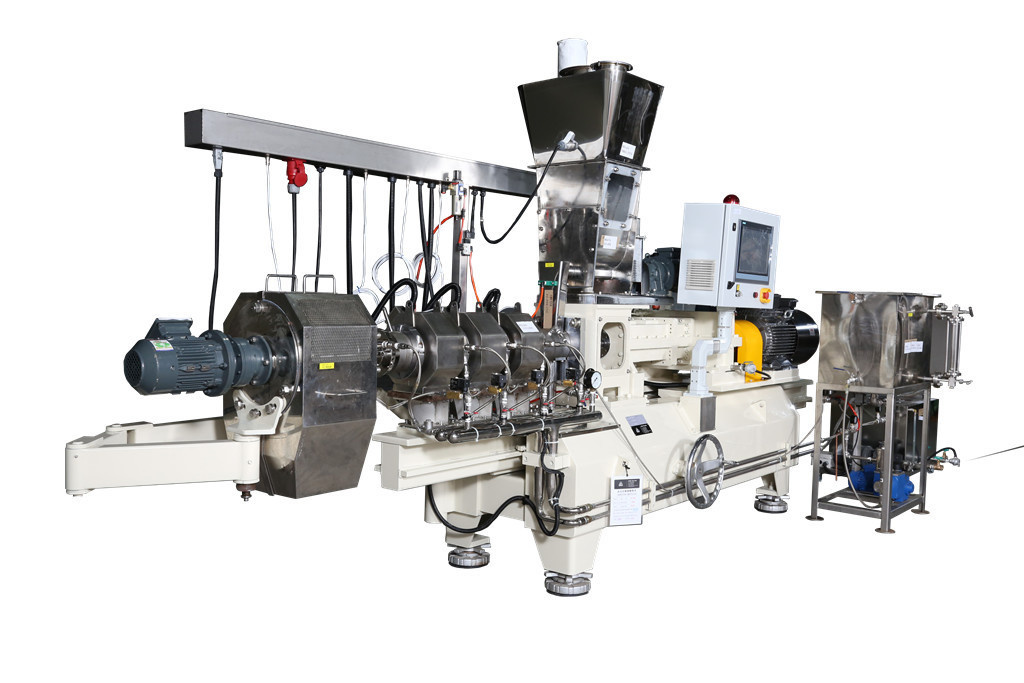

Specification of Co-rotating Twin Screw extruder

| Model | EP-50D | ZPT-58D |

| Main Motor (HP) | 40 | 50 |

| Capacity1 (kg/h) | 25-30 | 50-60 |

Note:

1) Texturized Vegetable protein

Products of Texturized Vegetable Protein

VM-M Mushroom Type

VM-Chunk Type

VM-Shredded Ball Type

TVP after reconstitution in water