Carousel Dryer and Cooler for Food

Food is one of the human necessities. Long ago, the human population is

low, and humans can depend on foraging to gather food. With the increase

of human population, they shifted to farming for producing a higher

number of food.

Food is naturally perishable, so a method of preservation is

needed to reduce or stop spoilage.

Drying is one of the most effective ways of preserving foods,

usually involving the removal of water by application of heat. Besides

energy consumption, the drying process will change the color, texture,

odor, and other properties of solid products. Hence it is of the utmost

importance for a dryer to

dry effectively with low energy consumption.

The

carousel dryer is developed to dry the food with small space

requirement, quick product change, lower energy requirement, lower air

volume requirement, gentle tumbling across the drying deck, and uniform

moisture.

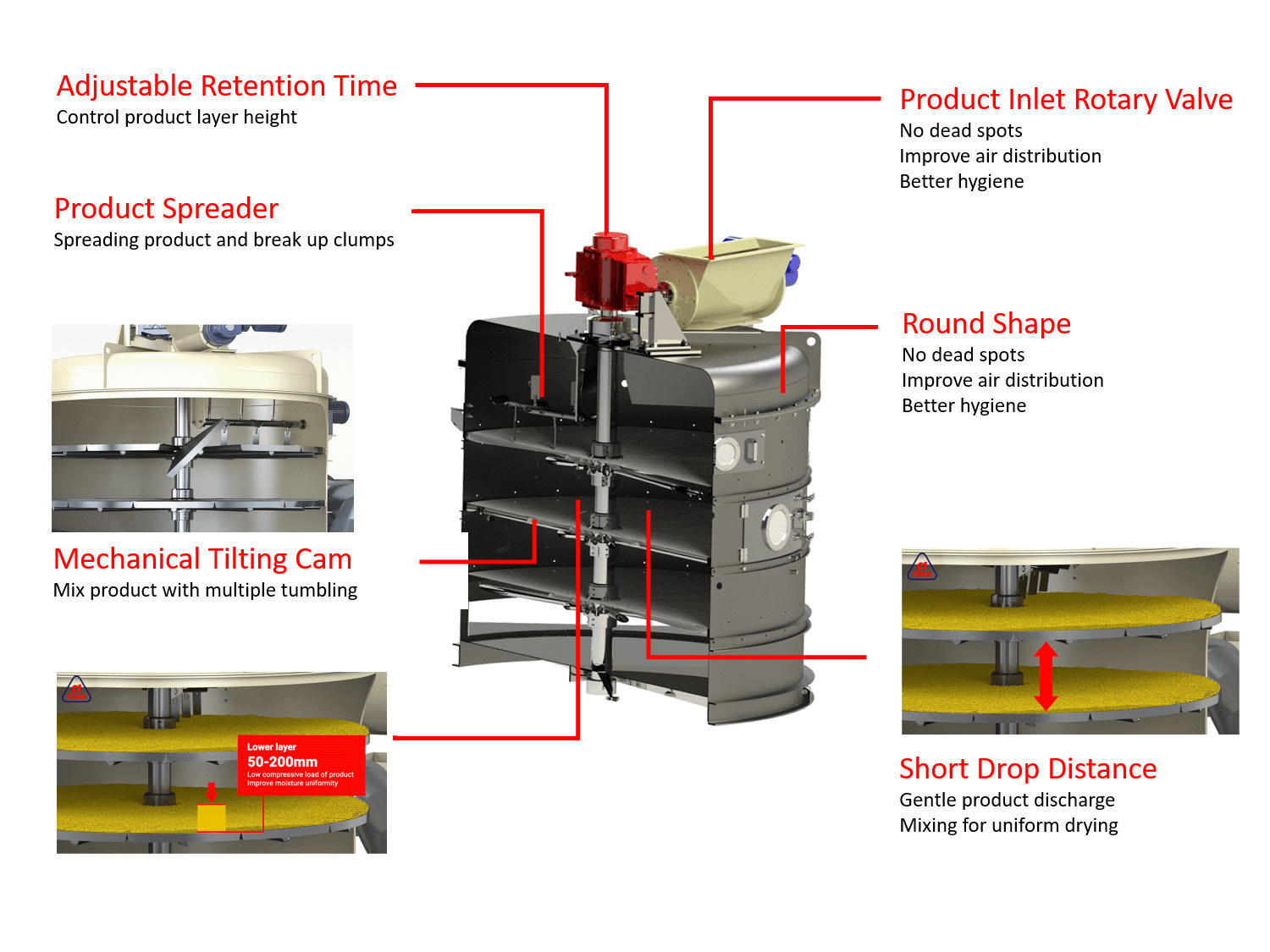

Detailed Design of Carousel Dryer

Designed for the production of high-quality food

-

Adjustable retention time

Control of product layers -

Product inlet rotary valve

No product damaging even with 100% filling -

Round shape

- No dead spots

- Improve air distribution

- Better hygiene -

Product spreader

Spreading product and breaking up clumps -

Short drop distance

Gentle product discharge and mixing for uniform drying -

The lower layer 50-200mm

- Low compressive load of product

- Improve moisture uniformity -

Mechanical tilting cam device

Mix product with multiple tumbling

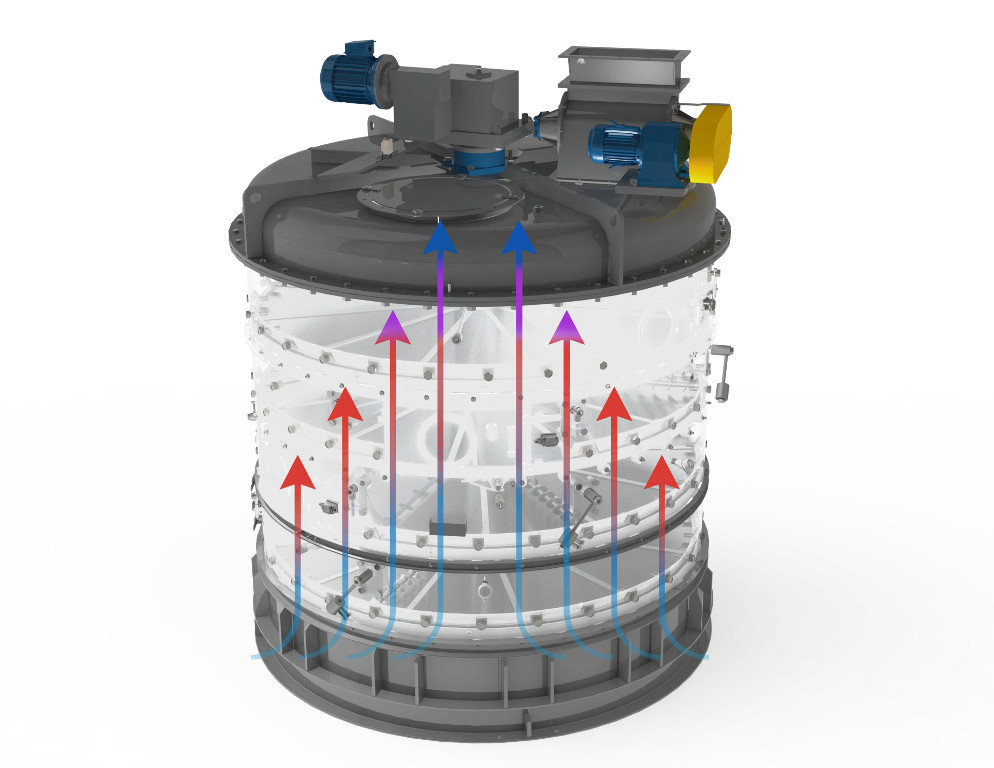

Go Round for Gentle and Uniform Drying

Each pellet is carefully treated

THE PROCESS

- A round-shaped carousel dryer consists of several slowly rotating circular decks. The product to be dried is fed from the top tray

- After nearly one revolution, the product is discharged onto the next subjacent deck. During discharge, the process product is mixed, leveled again

- This process is repeated until the product is discharged from the last tray into the outlet

- Change of product without downtime, just allow one deck to be fully emptied

- The airflow is vertical and goes through the perforated circular trays

- The product is moving in circles in a fixed counter-flow airflow

- The product flow is first-in, first-out(FIFO). Every pellet is getting the same treatment while passing different air volumes and temperatures

- The result is optimum drying uniformity

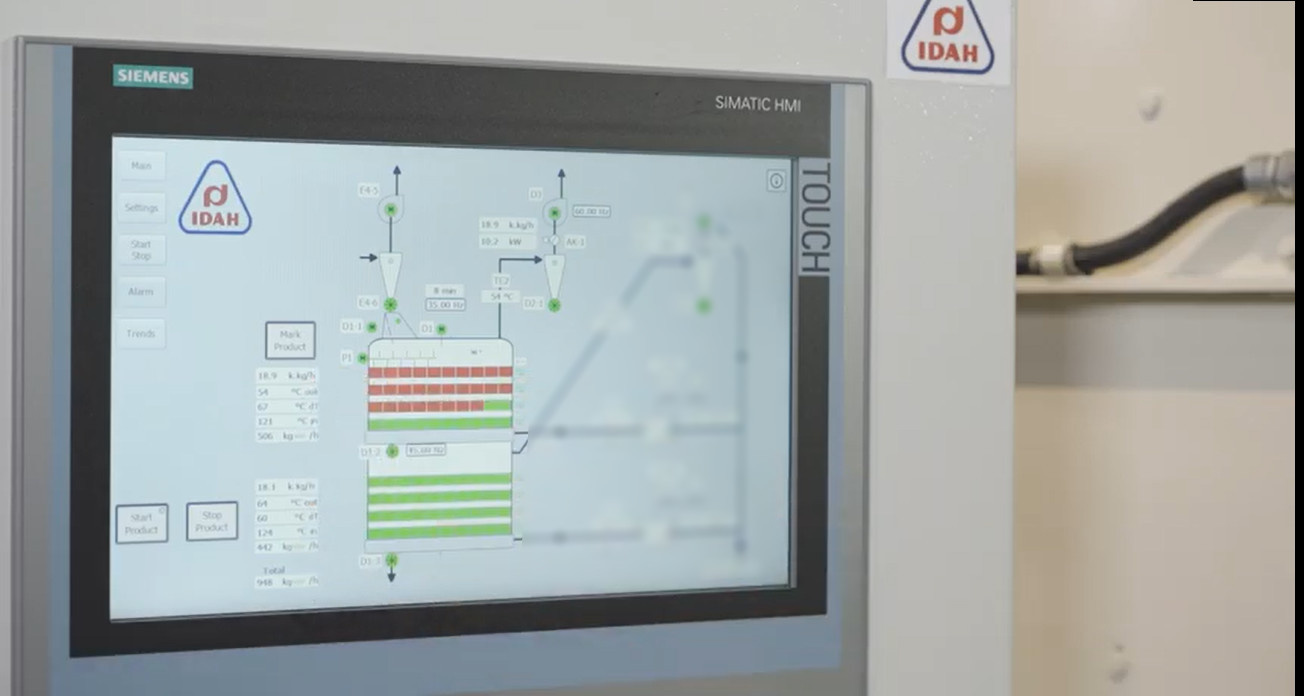

New Moisture Control System

In 2020, IDAH incorporated a new moisture control system. The intelligent PLC system will incorporate the moisture sensor in the outlet of the dryer. This sensor will commence the dryer parameter correction:

-

Temperature, air volume, and retention time control

The control philosophy of the dryer will be a crucial factor in the overall performance. To get maximum profit for the uniform drying performance of the Carousel Dryer, we control the energy absorption from the product by controlling the temperature, air volume, and retention time. -

Water evaporation calculations

The calculation system helps operator accurately control their product moisture and keep track of any changes in the parameters during production. The system enables the operator to achieve and maintain the target moisture quickly and efficiently -

Energy efficiency indication

With the automatic calculation, the operator can see the efficiency of the drying process and take rapid measures whenever the numbers are abnormal

| Product | Capacity (kg/h) | Moisture in (%, wb) | Moisture out (%, wb) | Type | Location |

| Natural cane sugar | 1,500 | NA | 1 | T300.3 | Germany |

| Pistachios | 2,000 | 22 | 5 | T225.5 | Germany |

| Bread crumbs | 1,700 | 38 | 10 | T300.2 | Netherland |

| Cacao nibs | 5,100 | 30 | 11 | T300.5 | Brazil |

| Product | Capacity (kg/h) | Moisture in (%, wb) | Moisture out (%, wb) | Type | Location |

| Whole meal | 630 | 40 | 12 | TK300.2.1 | Germany |

| Almonds | 2,000 | 45 | 27 | TK300.3.2 | Germany |

| Maize germs | 3,000 | 17 | 12 | TK260.4.2 | Italy |

| Coffee beans | 5,800 | 16 | 12 | TK300.3.2 | Italy |

| Maize flakes | 2,500 | 22 | 14 | TK300.3.4 | China |

| Extrudes for snakes | 700 | 12 | 3 | TK200.2.1 | Switzerland |

| Wheat nuts, honey c. | 5,000 | 20 | 10 | TK300.6.2 | France |

| Rice, macaroni | 1,200 | 13 | 8 | TK260.3.1 | Brazil |

| Flour additives | 1,100 | 20 | 8 | TK300.3.1 | Denmark |

| Product | Capacity (kg/h) | Temperature in (°C) | Temperature out (°C) | Type | Location |

| Sweets, caramel | 800 | 80 | 25 | K260.2 | Germany |

| Extruded cereal meal | 830 | 100 | 20 | K260.2 | Germany |

| Almond, apricot pips | 1,000 | 55 | 20 | K200.4 | Germany |

| Spices | 600 | 60 | 15 | K260.3 | Sweden |

| Cereal flakes | 1,170 | 130 | 20 | K200.3 | Netherland |

| Bread crumbs | 2,000 | 100 | 20 | K260.2 | UK |

| Milk replacement feed | 5,300 | 35 | 4 | K300.6 | Switzerland |

Dryer with Moisture Uniformity for You

Our team of expert engineers has worked intensively to improve the dryer technology even further to increase the drying process efficiency. IDAH considers all of your process requirements, moisture uniformity, efficient energy transfer, easy operation, and minimal downtime to select the dryer with moisture uniformity for your industry.