IDAH Turnkey Projects

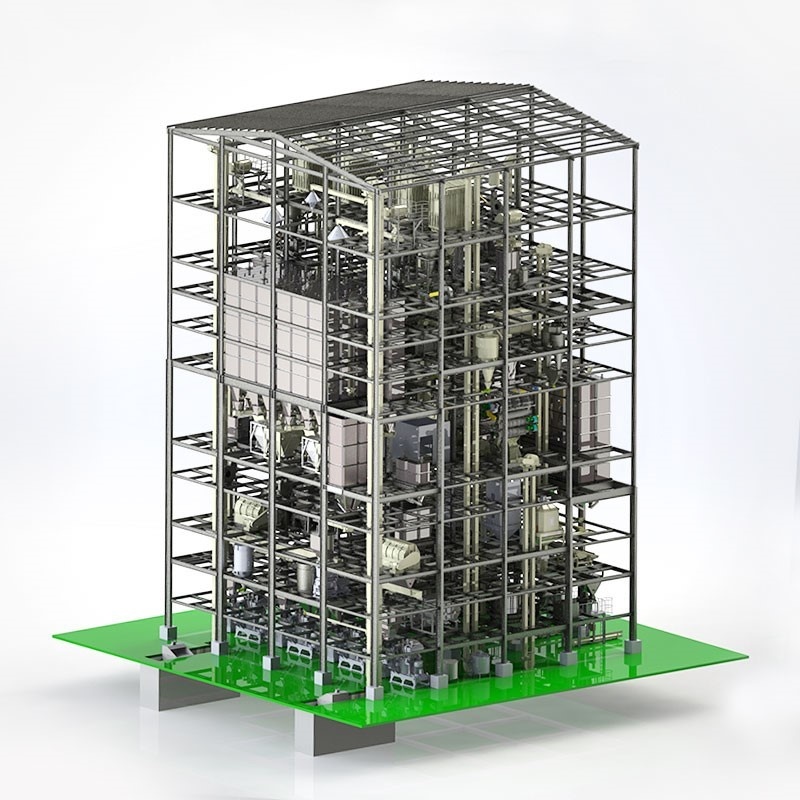

IDAH applied a 3D design program to simulate the process flow, to reduce the time and money needed while manufacturing machines, constructing machine towers, and machines installation. IDAH machinery and spare parts are produced with optimal design and conforming the accepted standards of safety and quality, providing premium quality and reliable products. Not only standard machinery, but IDAH also provides customizable machines for customers.

Project in Andra Pradesh, India

Project in Andra Pradesh, India

Our Turnkey Solution

Our 3D design program can calculate the static machine loading on each of the steel structures. You can consult the machine-loading data with the local civil engineer. To build a sturdy machine tower, the engineer will measure the soil structure, wind speed, and other factors to determine the type and size of the foundation or basement.

IDAH offers machine tower layout and structure design drawings according to customer requests. We always designed the most optimum design conforming to the local safety regulation of the country. You can also use these drawings for communication with the local contractor during construction.

The design of the bin tank is essential to ensure smooth material transportation through the outlet holes and chutes. The placement of the bins and tanks is important to guarantee a smooth material flow for optimal production timing.

Placement and installation of machines hold a role in ensuring a smooth production flow. IDAH works together with the customer and the construction company to ensure that the proper machine installation.

-

Duct and hopper connection:

The fieldworker will connect hopper, duct, water pipes, air pipes, and steam pipes to complete the whole process line. -

Wire and cable connection:

A proper installation of electric power wire and control cable the motor to the control cabinet and power source to guarantee safe operation.

-

Motor and control test:

The whole process control system has to follow check with HMI/control panel software. Before whole process testing, we have to test the motor for each machine individually. -

Process commissioning:

After finishing the machine installation. Our expert team will commence a thorough pre-run inspection, machine run-testing, operator training, and know-how technology transfer.

Our Turnkey Service Fields:

- Aquatic feed mill (shrimp feed, fish feed)

- Extruded floating, slow sinking, and sinking fish feed mill

- Animal and poultry feed mill

- Pet food and treat plant (dry pet food, semi-moist pet food treat)

- Corn and soybean extrusion cooking mill

- Extruded snack plant

- Textured Vegetable Protein (TVP)

- High Moisture Meat Analogue (HMMA)

- Fertilizer pelleting plant

- Biomass and wood pellet plant

- Premix and Concentrates