To support provide a balanced and stable feeding for the farmed fish, many producers have shifted to manufactured pellets. Based on the behavior in the water, the fish feed can be divided into floating feed, slow-sinking feed, and sinking feed. IDAH offers you an extrusion and pellet mill to produce high-quality fish feed. Depending on the types of fish feeds, sinking feeds can be made on both pelleting and extrusion systems. Pellet mills can only make fast sinking feeds. For example, milkfish feeds are still common to be made on pelleting lines thanks to advancements in pre-conditioning and post-conditioning technology. However, extruder offers more products characteristics from fast sinking, slow sinking, and floating.

Raw Material

The raw material consists of coarse and powdery material

Pre-grinding

Optional step for coarse material.

Pre-grinding will lower the

energy needed for ultra-fine grinding.

Daily Tank Storage

In general, the fish feed line will utilize 12 raw material bins.

Every bin will be filled with around 5-6 batches of material.

Dosing and Weighing

The material will be dosed based on the formula.

In the fish

feed line, usually, the material will be processed by batch.

Post-grinding

Post-grinding is the final size reduction in the system.

It is common to use a pulverizer for producing ultra-fine powder.

Dry mixing

In this step, trace ingredients such as vitamins and minerals will be added and mixed.

Extrusion

Extrusion starts with pre-conditioning and hydrating by adding steam

and water or other liquid.

The material will undergo high pressure, high temperature, and

shearing in the barrel, and then be formed by mold at the outlet.

Drying

Drying in extrusion is a must, wet pellets will enter the dryer and

come out as dry pellets.

No matter horizontal or vertical dryer, good moisture control

is the most important feature that a dryer needs.

Coating (optional)

It is common to coat the pellets with oil or enzymes to increase the

nutrient value of the pellets.

Depending on the liquid coating level, a drum coater or vacuum

coater can be used.

Cooling

Cooling utilizes ambient air to cool down the hot pellet from the

dryer.

Thorough cooling is needed to prevent condensation inside the

packaging.

Packing

Packing gives protection to the pellets and also give easiness to handle and transport to customer's hand

Extrusion process description for aquatic feeds

Oil coating is needed to increase the nutritional value and palatability of the feed. Depending on the fat content that needs to be added, a drum coater or A vacuum coater can be chosen.

Cooler lowers the temperature of the hot pellets to +3°C of room temperature by utilizing ambient air.

All pellets will go through a vibration sieve to remove any irregular pellets or impurities before bagging.

Weighing cell and bagging machines bag pellets with chosen quantity ex: 20 Kg. or 25 Kg. per bag and seal the bags for storage. Finished products can also be loaded by trucks or in container bags.

Features and Benefits of IDAH Process Design and Equipment

IDAH firmly believes in a strategy of design fit for purpose. We recognize the constraints our customers face with rising ingredient costs, energy costs, and overheads costs, yet in the face of these challenges, it is still expected that high-quality products be supplied into a very competitive market. Our design philosophy is to work continuously to refine and improve processes and equipment to maximize the success of our customers. The following describes some of the features and benefits resulting from this philosophy.

We design our equipment for continuous operations and fulfill the expectation for minimal downtime. Our mission is to see our equipment still working years after installation, with only maintenance required being routine maintenance caused by normal fair wear and tear.

Two perspectives are influencing the formulation: culturing performances and efficiency of the machinery. For example, choosing the right starch source (types of flour) is essential. Inappropriate starch sources will lower the steam incorporation level and causes jams at the pellet mills. Fat and moisture content play inseparable roles in the hammer mill and pulverizer throughput. Formulation with high fiber content not only increases the risk of broken pellets, lowering the water stability of the pellets. High fiber content also increases the wear of all machinery in the process. Reducing the use-life of the parts such as the hammers, screens, and dies.

We offer a range of mixers, depending on customer needs and preferences. Our mixers are all of the very rugged design and we continue to develop new features, such as geared shaft drives on our twin shaft mixers, which reduce noise, energy costs, and maintenance costs.

We firmly believe in the benefit of even particle reduction to

ultra-fine powder. The typical target is to reach more than 95% passing

through a 60 mesh screen. It is impossible to efficiently produce

small-size products with size 2.0 mm and below without this ultra-fine

grind process. Ultra-fine grinding will increase production efficiency

and end product quality during the production of larger-size products.

It will also open the possibility to utilize less expensive starchy

ingredients.

IDAH understands that many production practitioners

might worry about the extra energy cost of utilizing a pulverizer, which

is why we designed a revolutionary pulverizer that runs at much lower

energy costs. The ability to substitute with cheaper ingredients cost

will compensate for the small extra energy requirement of the

pulverizer. The ultra-fine raw material will produce a smooth, shiny,

and water-stable product.

We always recommend the pre-hydration in the pre-conditioning process. The hydration of dry ingredients at this production stage improves the throughput, lowers energy costs, and increases product quality. To evenly feed the pre-hydrated mix to the pellet extruder, we supply the DDC with a steam and liquid addition system for liquid incorporation. The paddles on the twin rotating shafts will help to incorporate dry material, steam, and added liquids.

The independent drive on each shaft of the IDAH twin shaft lowers power consumption and noise. The paddles' reverse rotation allows completely emptying the chamber. The misting steam and water injectors further improve conditioner performance. The following conditioner system used steam jacketed (or heat jacketed) to create a homogenous mix with little to no free water. Insufficient pre-conditioning will cause cracks on the pellet surface and create dust fines.

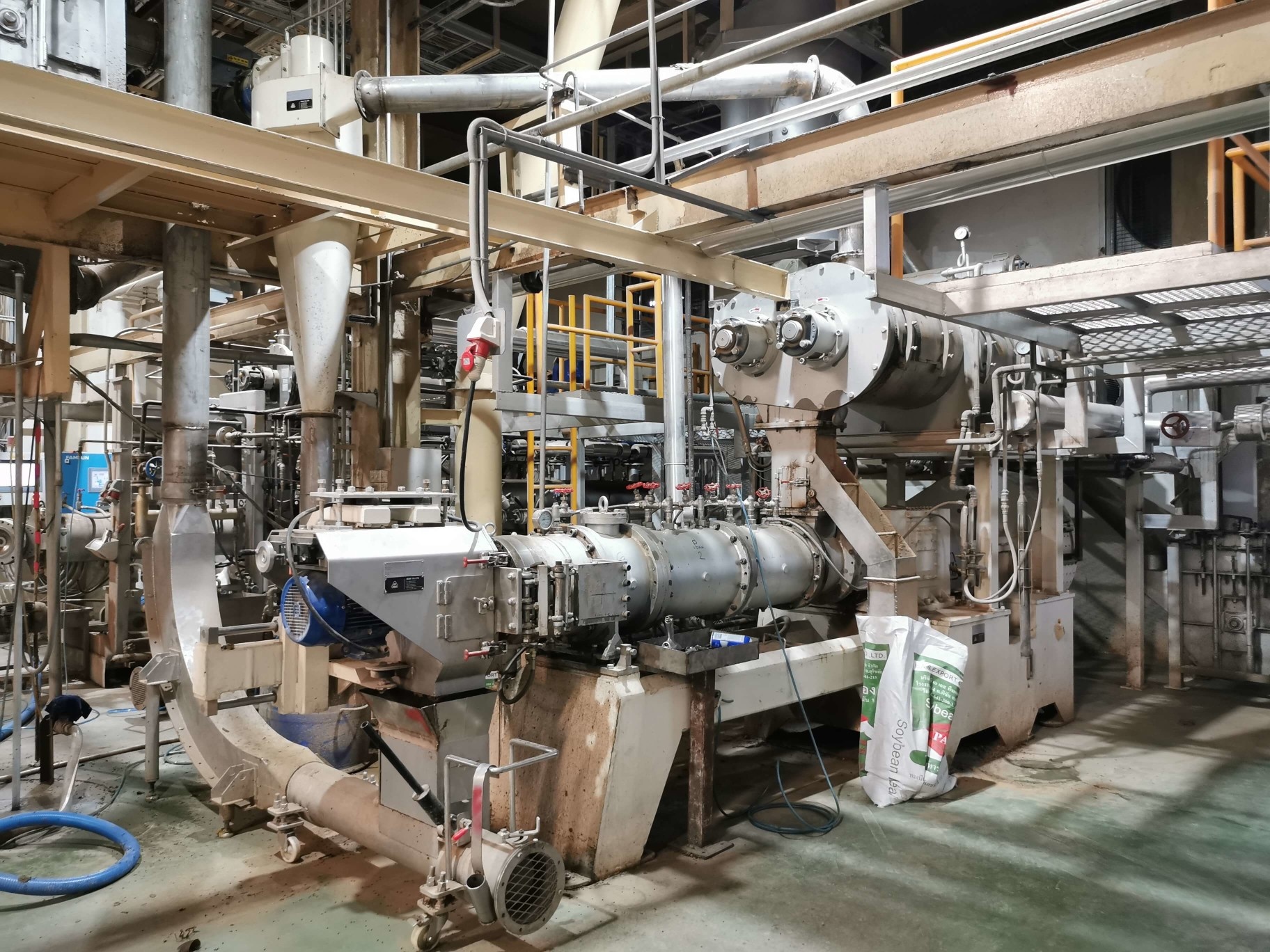

The ContraTwin screw extruder is a guaranteed solution to increase product quality standards, with lower energy costs and wear costs. This extruder is suitable for processing high fiber formulations. Our machines typically make high-quality aqua feeds with specific mechanical energies of 25kWh/tonne or lower. The very positive conveying action inside these machines allows us to run high fiber and small diameter products at rates others find difficult to believe.

IDAH offers the carousel dryer T-series and the horizontal dryer

CDX-series for your drying solution.

When choosing the correct dryer for your application, moisture control

should be one of the most critical selection criteria. Moisture has a

direct impact on your product quality, production cost, and profits in

your business. One aspect of moisture control is uniformity, together

with drying result consistency–in-time will determine the target average

moisture content. The closer the average moisture to the maximum

moisture levels, then the less raw material is lost through over-drying,

generating more profit for your company.

The counterflow cooler is used for cooling pellet and extrudate. Warm (hot) pellets get into the cooling chamber, the suction fan will transport out the air inside the chamber, and fresh ambient air will enter the chamber from the bottom, promoting pellet cooling action. When pellets are accumulated and touch the high-level limit sensor, a pneumatic discharge swivel valve will operate immediately to discharge the products. Counterflow air heat exchange ensures to achieve high cooling efficiency.

In food and feed production, many kinds of ingredients with different properties are used. IDAH provides a high-efficiency mixer for mixing powder and liquid material depending on the formulation requirement. In many foods and feed production, additional liquid may be applied for improving the quality nutritional value, and palatability. IDAH mixing and coating ensured precise mixing for producing a high-quality product.

Specification of ContraTwin screw extruders (for Fish feed)

| Model | EP-76D | EP-156D | EP-156DL | EP-190D |

| Main Motor (HP) | 150 | 250 | 350 | 450 |

| Capacity1 (t/h) | 0.5-1.0 | 1.0-5.0 | 2.0-5.0 | 6.0-8.0 |

| Capacity2 (t/h) | 1.0-2.0 | 5.0-7.0 | 5.0-8.0 | 8.0-12.0 |

Note:

1) Aquatic floating feed, plate die hole size Ø 1.5 - 4.0 mm

2) Aquatic floating feed, plate die hole size Ø 4.0 - 10.0 mm

Specification of Single shaft screw extruders (for Fish feed)

| Model | EP-150 | EP-170-6 | EP-218 | EP-238 |

| Main Motor (HP) | 150 | 250 | 350 | 450 |

| Capacity1 (t/h) | 0.5-1.0 | 1.0-5.0 | 2.0-5.0 | 6.0-8.0 |

| Capacity2 (t/h) | 1.0-2.0 | 5.0-7.0 | 5.0-8.0 | 8.0-12.0 |

Note:

1) Aquatic floating feed, plate die hole size Ø 1.5 - 4.0 mm

2) Aquatic floating feed, plate die hole size Ø 4.0 - 10.0 mm

Products of Fish Feed Extrusion

Floating Fish Feed with red colorant, Ø 4.0 mm

Floating Fish Feed, Ø 1.5 mm

Vacuum coated Sinking Fish Feed, Ø 4.0 mm, total oil content 25%