Other than chicken feed, duck feed is also a major type of poultry feed. The formulation for duck feed contains a high concentration of fiber and makes the mash very puffy. It is a rule of thumb to know that it is relatively harder to treat any formulation with a high fiber level using massive direct steam. Over-dosed direct steam will eventually create cracks on the surface. The concentration of fiber and pellet quality is equally proportional. However, a high concentration of fiber will lower the efficiency of pelleting capacity. Around one percent of water can be added to the mixer to compensate for any raw material for pre-hydrating. This pre-hydrating by the mixer will help in the pelleting process.

Raw Material

The raw material for cattle feed consists of coarse and powdery material

Pre-grinding

Optional step for coarse material.

Pre-grinding will lower the

energy needed for ultra-fine grinding.

Daily Tank Storage

Daily tank storage will contain the material needed for production

that day.

Some material from the silo will be placed in this daily tank

before entering the flow of feed production.

Dosing and Weighing

The material will be dosed based on the formula.

Post-grinding

Post-grinding is the final size reduction in the system.

It is common to use a pulverizer for producing ultra-fine powder.

Mixing

In this step, trace ingredients such as vitamins, minerals, and other liquid materials will be added.

Powder Feed (Mash Feed)

Pelleting

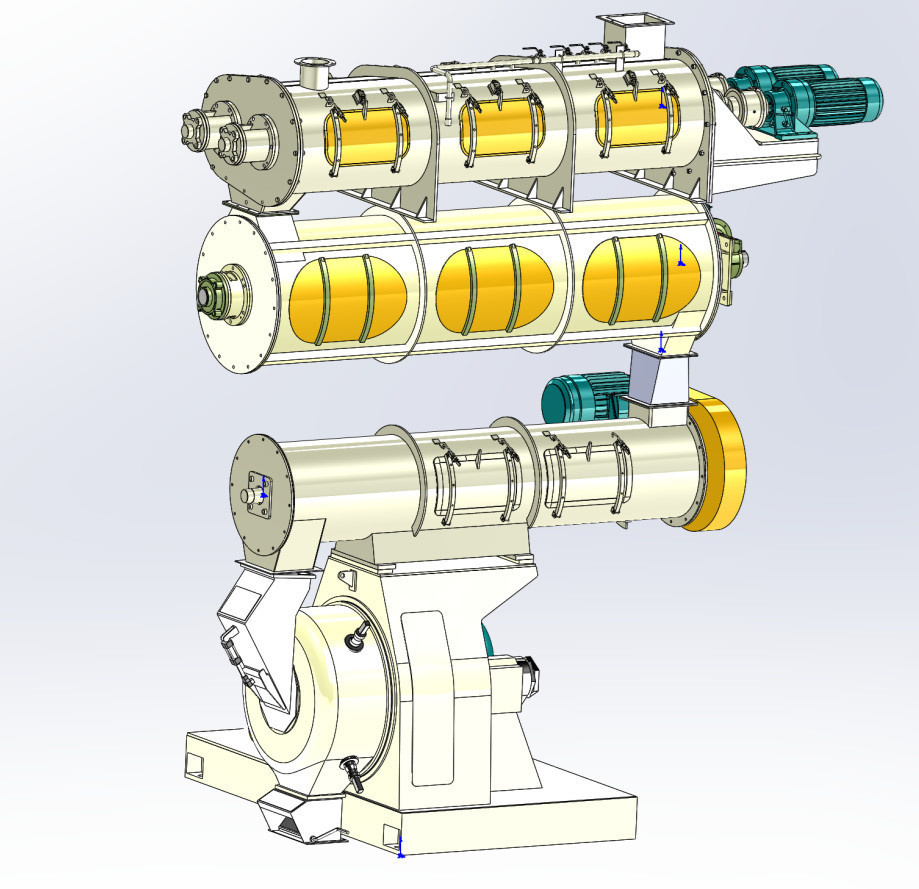

Pelleting starts with pre-conditioning, adding steam to further hydrate, and cooking the material before entering the pelleting chamber to be formed into pellets.

Cooling

Cooling utilizes ambient air to cool down the hot pellet from the

post-conditioner (or dryer).

Thorough cooling is needed to prevent condensation inside the

packaging.

Pelleted Feed

Crumbling

In animal feed production, it is common to crumbler the feed.

This particle reduction is needed for easier consumption in

smaller animal or poultry

Packing

Packing gives protection to the pellets and also give easiness to handle and transport to customer's hand

Pelleting process description for specialized animal feeds

The counterflow cooler is used for cooling pellet and extrudate. Warm (hot) pellets get into the cooling chamber, the suction fan will transport out the air inside the chamber, and fresh ambient air will enter the chamber from the bottom, promoting pellet cooling action. When pellets are accumulated and touch the high-level limit sensor, a pneumatic discharge swivel valve will operate immediately to discharge the products. Counterflow air heat exchange ensures to achieve high cooling efficiency. Pellet is cooled until reaching ± 5 °C from the ambient temperature.

Pellets are conveyed through a sieve to remove impurity and deformed pellets. Fines and deformed pellets are recycled back to bins before the pellet mill. The sieved pellet of different sizes is stored in individual bins.

Finished pellets will be placed in bags or other transportation vessels to the reseller or customer site.

IDAH crumbler series is designed for high capacity and highly efficient particle reduction. Three types are available for every industry application. Every crumbler is equipped with the feeder on the top, to control the throughput of the product. The roll gap is easily adjustable to achieve the required granulation.

Features and Benefits of IDAH Process Design and Equipment

IDAH firmly believes in a strategy of design fit for purpose. We recognize the constraints our customers face with rising ingredient costs, energy costs, and overheads costs, yet in the face of these challenges, it is still expected that high-quality products be supplied into a very competitive market. Our design philosophy is to work continuously to refine and improve processes and equipment to maximize the success of our customers. The following describes some of the features and benefits resulting from this philosophy.

Poultry feed contains a high amount of grains and that means a high concentration of fiber. Good quality of pre-conditioning is the key to success in making poultry pellet feed. Enough direct and indirect steam heat source and moisture will soften the mash with high elasticity. cooked starch is the perfect binder to form pellets.

Too much fat added in the formulation will create a high amount of fines formation during pelleting. It is suggested to add 1% of fat in the mixer and this will lower the wear on the dies and improve the throughput of the pellet mill. Any additional fat is suggested to evenly spray on the pellets to improve the fat contents and quality of the pellet surface.

Specification of Pellet Mills (for Poultry feed)

| Model | PM-42R | PM-51R | PM-53R | PM-53F | PM-635D |

| Main Motor (HP) | 125 | 150 | 200 | 215 | 300 |

| Operation Capacity1 (t/h) | 3-4 | 4-5 | 6-8 | 10-12 | 13-15 |

Note:

1) Broiler Chicken Feed, pellet die hole size Ø 3.0 mm, moisture content<12%, oil content <7%