Cattle Feed

The animal feed comes in many forms. Pelleted or mash feeds are popular in the market. Both products share a similar production sequence until the mixing process. pelleted feed needs to undergo pellet mill, cooler, and sifter after the mash is prepared.

Mash feed is a form of a complete feed that is finely ground and mixed so that animals or birds cannot easily separate the essential nutrients. The purpose of feeding mash diet is to provide a

well-balanced diet, give greater growth unification, less death-incurred loss also feeding mash feed is more economical. When producing mash feed, the material undergoes pre-grinding before mixing and packing. Pelleted feed is the continuation of mash feed. The purpose of pelleting is for easy transport and feeding. The nutrient value in every pellet is the same, so farmed animals will consume all the good nutrients incorporated inside the pellets.

READ MORE

Specialized Animal Feed

Other than chicken feed, duck feed is also a major type of poultry feed.

The formulation for duck feed contains a high concentration of fiber and makes the mash very puffy. It is a rule of thumb to know that it is relatively harder to treat any formulation with a high fiber level using massive direct steam. Over-dosed direct steam will eventually create cracks on the surface.

The concentration of fiber and pellet quality is equally proportional. However, a high concentration of fiber will lower the efficiency of pelleting capacity.

Around one percent of water can be added to the mixer to compensate for any raw material for pre-hydrating. This pre-hydrating by the mixer will help in the pelleting process.

READ MORE

A New Generation Dryer, Developed for The Shrimp Feed Industry

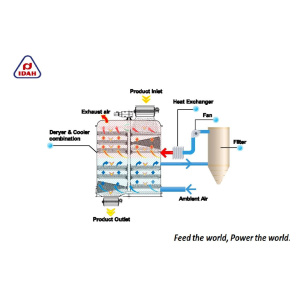

A new generation, developed for the shrimp feed industry, multi-deck carousel dryer/cooler is designed for better uniformity and optimum moisture control.

This compact dryer-cooler has an advanced air system, utilizing the air from the cooler into the dryer air system, thus increases the overall efficiency, and reduces 50% of the exhaust air volume.

The moisture control is performed on the finished cold product done by First-in-First-out (FIFO) product flow with a short overall retention time.

Easy, quick, and accurate moisture control has a big impact on product quality and cost price.

READ MORE