New way of drying shrimp feed

This article is published in Aquafeed: Advances in Processing & Formulation Vol. 12 Issue 2 2020

New Way of Drying Shrimp Feed

In a modern shrimp feed pelleting process increasingly more liquids are

added into the mash feed. This in combination with long-term steam

conditioning is increasing gelatinization and water stability for better

end-product quality. Recipe cost optimization can be limited if there

are drying capacity restrictions. In a lot of situations, moisture

removal with only cooling is not enough anymore and an extra drying step

is required. Moisture control is more and more crucial for quality and

cost price reasons.

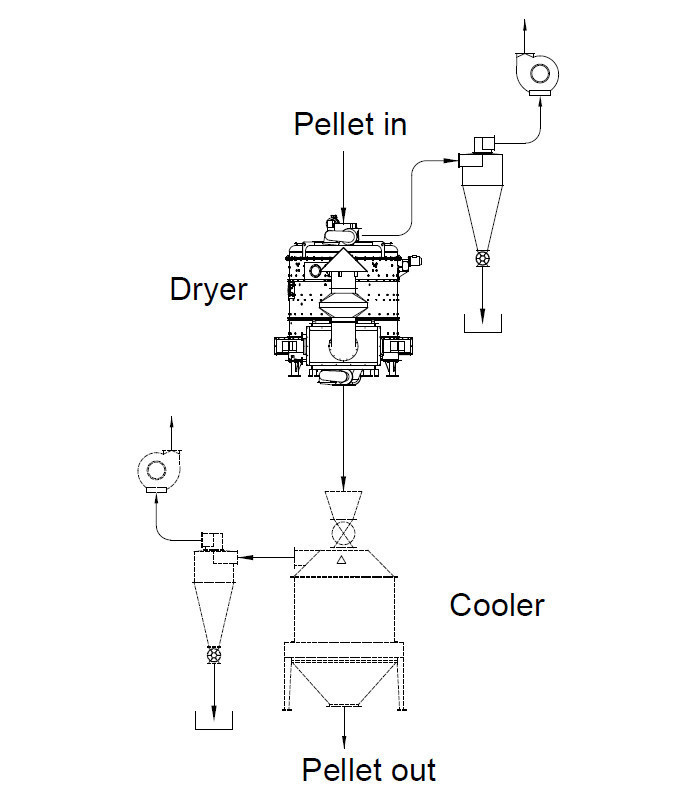

In traditional shrimp feed processing, there is a separate machine for

drying and cooling, the products are dropped from the pellets mill/post

conditioner into the dryer for moisture removal, then into the cooler to

cool down the product with ambient air. Moisture control is done by

checking the product after the dryer and corrections by measurements of

finished product moistures. The process is shown in figure 1.

Figure 1. Traditional dryer and cooler flow chart

Figure 2. Combination of the dryer and cooler flow chart

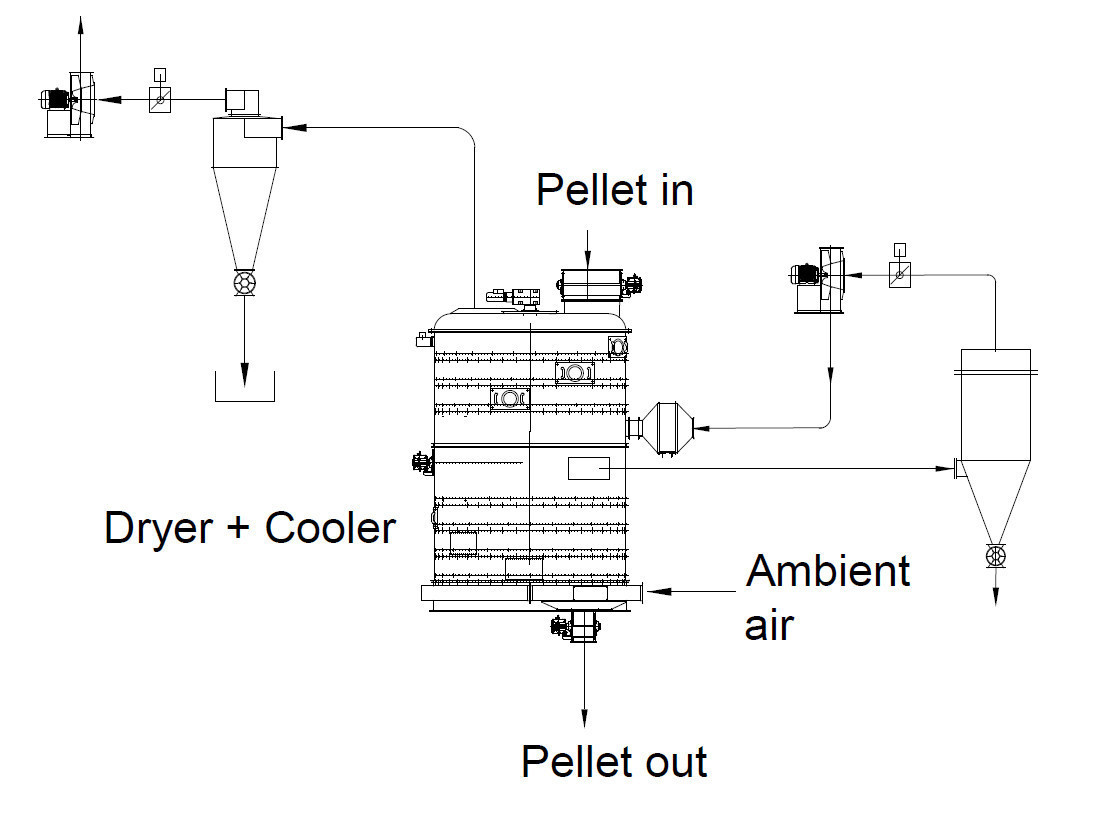

Integrating drying and cooler in one solution

New in the market is the carousal dryer and cooler combination, with a

unique solution for both energy efficiency and precise moisture

control.

Optimizing moisture control is a lot easier if the retention time is

short and the dryer and cooler have a first in first out (FIFO)

principal. Plus the moisture can be controlled directly after the

cooler so the impact of more or less water evaporation in the cooler

is already taken care of in the total moisture control cycle.

Therefore integration of the dryer and cooler into one compact machine

with a FIFO discharge principal like the carousel dryer will give an

outstanding control performance. The flow chart is shown in figure 2.

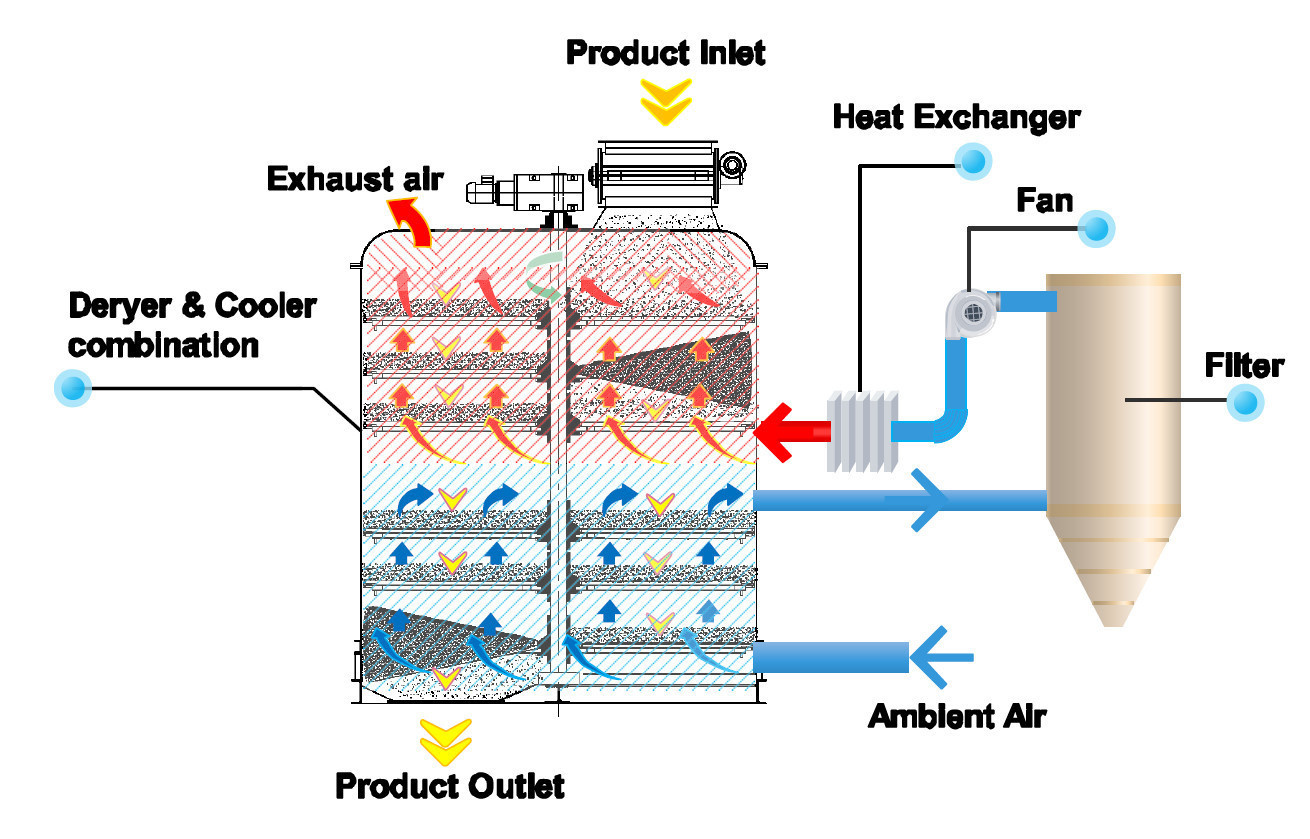

The carousel working principle

The complete unit consists of an upper drying zone and a lower cooling

zone. The product comes in through a rotary seal and going round in the

dryer. After nearly one revolution, the product is gently discharged and

mixing onto the next lower tray. This process is repeated until the

product is discharged from the drying zone into the cooling zone and the

product drops from the last tray into the outlet. Where a rotary seal is

avoiding air leaking.

Ambient air is cooling the product, filtering, and heating is used as

drying air for the upper section. Because of the multiple tumbling and

optimal air use in the round dryer, the drying process is extremely

efficient resulting in a low exhaust air temperature. Figure 3 indicates

the products and airflow scheme.

Figure 3. Dryer cooler combination product and airflow scheme.

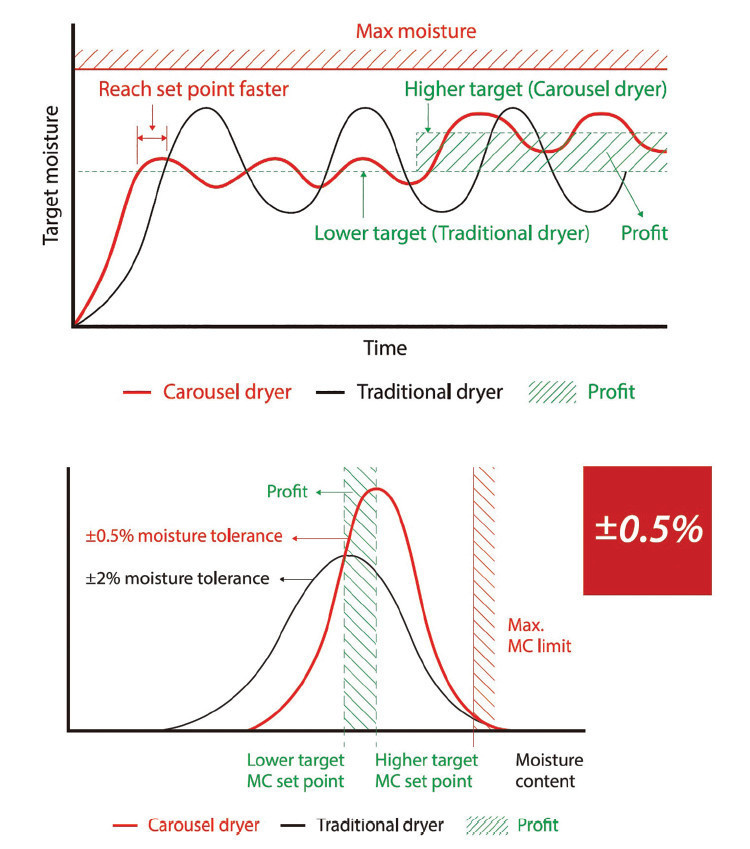

Improving product moisture control

Managing the temperature and moisture content of the finished product

is the main task for the drying and cooling process. However, when the

feed is overdried this causes material loss as well as extra energy

consumption. When the feed is too wet the product will have a higher

risk of quality degradation and mold growth.

A carousel dryer is working according to the first in first out (FIFO)

characteristic. Having the product circling round in a steady and

controlled airflow all the products will get the same heat treatment

and retention time. Combine this with a unique and easy control

system, providing real-time monitoring and modification of the drying

parameters such as drying air temperature air volume, and retention

time.

Because the carousel dryer is giving a uniform and constant moisture

level the target average moisture can be optimized saving energy and

saving raw materials. Figure 4 shows the moisture uniformity

comparison between the carousal dryer and traditional dryer

Figure 4. Moisture uniformity comparison between the carousel dryer and traditional dryer

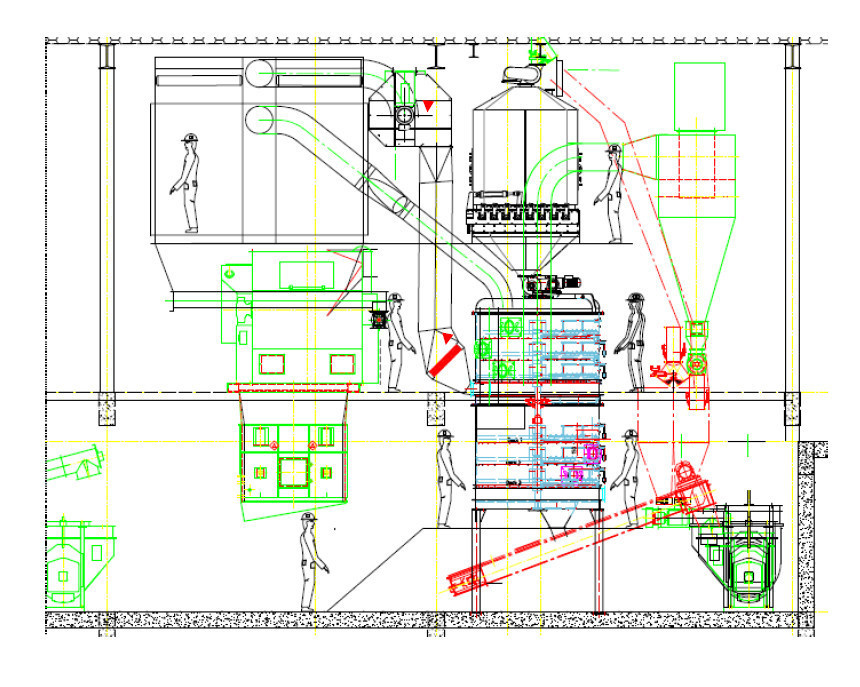

Figure 5. Dryer cooler combination layout

Improving energy efficiency

The drying and cooling process accounts for a significant part of the

overall energy consumption, rising energy costs, and sustainability

awareness regarding energy consumption have driven feed manufacturers to

request further support to improve their drying and cooling functions.

To maximize energy efficiency we have to look into:

1) Maximum use

of warm product energy

2) Minimize the amount of water evaporation

3) Minimize energy loss with the exhaust air.

By using the cooling air as makeup air into the dryer we reuse the

product energy and limit the amount of exhaust air. Due to the high

drying efficiency, the exhaust air temperature is also low reducing the

loss of energy by the already low exhaust air volume. Low exhaust air

volumes will also reduce the cost of odor treatment if required.

Reducing the space required

Process improvement or an upgrade in capacity is asking for the

introduction of new equipment into the facility. Space limitations have

to be overcome.

The carousel dryer is already more compact than a normally used dryer,

the dryer - cooler combined design has even more space requirement

advantages as shown in figure 5, in the limited available space the

cooler was positioned high in the building. The carousel dryer-cooler

positioned under the post conditioner is avoiding the hot product

transport and a lot of air ducting.

Potential savings

For example, using cooling air to make up air for the dryer. Assume the

the temperature differential between the ambient and cooler exhaust air

is 25°C you save up to 30 kg/t steam. At the same time, you will reduce

the amount of exhaust air by 50%, reducing odor treatment cost

significantly if required.

Getting a better moisture control for example 0.5% is saving not only

about 10 kg/t steam consumption in the dryer but even more important

saving 0.5% raw materials cost and have a 0.5% higher output capacity.