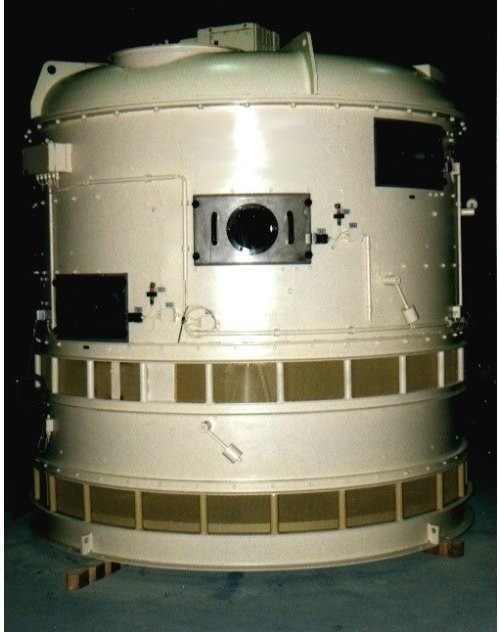

Carousel Dryer for Drying Bakery Grist / Germany

This customer utilizes our carousel dryer-cooler for processing the bakery

grist. Bakery grist is a pre-processed dough-like mass consist of coarsely

ground cereals, intended for baking whole-meal bread. When entering the

dryer, it is quite pasty and sticky. The dryer-cooler is expected to lower

the moisture down to around 10%. The drying temperature must not exceed

50°C to preserve the nutritive value.

One problem encountered when processing this material is on the top drying

deck, the product stuck together and somewhat turns into a big lump with

around 3 meters diameter. This problem is solved when we equipped a device

to loosen up the product on the top layer of the carousel dryer resulting

in free-flowing bakery grist after drying/cooling. This process is needed

to ensure easy packaging.

Another problem that we need to consider is the heat exposure of the

material. According to Gunathilake, et al. (2018) it is important to

remember that prolonged heat exposure on crop products may induce

physicochemical changes in the grain, so it is often required to directly

cool the material right after drying. This requirement can easily be

fulfilled by using the combination of a carousel dryer and cooler.

Carousel technology is a proven technology used for many different

industries. Bakery grist can be dried by the combined dryer/cooler,

lowering the moisture from 14% down to 10% at the outlet. IDAH considers

all of your process requirements, moisture uniformity, efficient energy

transfer, easy operation, and minimal down-time to select the suitable

Carousel Dryer for your industry.

REFERENCE

Gunathilake, D. M. C. C., D. P. Senanayaka, G. Adileta and

W. Senadeera. 2018. Drying of Agricultural Crops. Research gate

publication. DOI: 10.1201/9781351132398-14

| Location: | Germany |

| Capacity: | 4.5 t/h |

| Moisture in: | 14% (wb) |

| Moisture out: | 8.5% (wb) |

| Retention time (dryer): | 23 min |

| Retention time (cooler): | 15 min |

| Type of machine: | #TK300.3.2 |

| FEATURES |

|

Dried bakery grist after drying in the carousel dryer/cooling