IDAH participated in Victam Asia 2024 in Bangkok

Our team had a great week at Victam Asia 2024. Thank you to everyone who visited our booth to experience the all-new TwinTech Extruder, Pellet Mill 7900 and other solutions for the animal feed, aquafeed and pet food markets.

READ MORE

CPM to grow in aquafeed and pet food markets after IDAH acquisition

CPM plans to expand its capabilities in Asia and introduce the IDAH brand into Latin America where CPM has a growing and influential presence.

READ MORE

CPM Announces the Acquisition of IDAH

CPM, a leading solutions provider of process equipment and engineered technologies, today announced the acquisition of IDAH, a move that unites two industry leaders behind a shared mission to sustainably feed, fuel, and build a better world.

IDAH is eager to shorten the distance with you, our esteemed customers. We always try our best to provide the best machines, spare parts, and services for food, feed, and biofuel.

READ MORE

Third Generation Shrimp Feed Pelleting System

IDAH Pellet mill is known for its ability to handle high moisture feed mash up to 17% (%db), while maintaining a good post-conditioning process, to ensure pellets come out with high Pellet Durability Index (PDI) and water stability.

READ MORE

IDAH to exhibit in International Poultry Show Bangladesh 2023

We are pleased to announce that IDAH will be exhibiting at International Poultry Show 2023, and we cordially invite you to join and meet with us.

IDAH is eager to shorten the distance with you, our esteemed customers. We always try our best to provide the best machines, spare parts, and services for food, feed, and biofuel.

READ MORE

IDAH to exhibit in VIV Asia 2023

We are pleased to announce that IDAH will be exhibiting in VIV Asia 2023, and we cordially invite you to join and meet with us.

IDAH is eager to shorten the distance with you, our esteemed customers. We always try our best to provide the best machines, spare parts, and services for food, feed, and biofuel.

READ MORE

Merry Christmas and Happy New Year 2023

Season's Greetings from IDAH, Taiwan

It’s been a fantastic year and we hope we can continue doing business together in the forthcoming year.

In the meantime, have a wonderful Christmas and a happy holiday season.

READ MORE

Happy Diwali 2022

May this Diwali fill our lives with new hopes and dreams for the future. Let's celebrate the festival in the true sense by spreading joy and lighting up the world of others.

Have a happy, safe, and blessed Diwali!

READ MORE

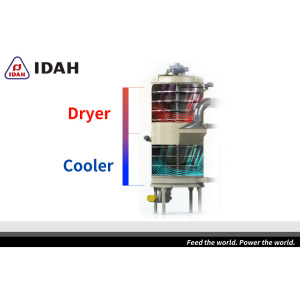

Total Moisture Control Solution exhibits in Victam Asia 2022

Dryer and Cooler in One Machine for Shrimp Feed have the benefits and features:

• Easy Moisture Control based on the after-cooled product, with moisture uniformity +/-0.5%

• Precise moisture control: no overdrying - saving steam & raw materials

• Recycling cooling air to save energy & reduce odor problems

IDAH is eager to shorten the distance with you, our esteemed customers. We always try our best to provide the best machines, spare parts, and services for food, feed, and biofuel.

READ MORE

Drying and Cooling shrimp feed in One machine

So what is the latest technology in drying and cooling shrimp feed? We considered all the requirements and the experience in the field and have developed a Generation 3 (G3) pelleting system that incorporates the dryer and cooler (TK-series) in one machine

READ MORE

IDAH to exhibit in Victam Asia 2022

We are pleased to announce that IDAH will be exhibiting in Victam Asia 2022, and we cordially invite you to join and meet with us.

IDAH is eager to shorten the distance with you, our esteemed customers. We always try our best to provide the best machines, spare parts, and services for food, feed, and biofuel.

READ MORE

Drying and Cooling of Bakery Grist at Its Finest with Carousel Dryer-Cooler (Published in dei-Germany).

Drying of bulk material can be a tricky and interesting process, simply because of the volume and number of material is larger. In order to provide an optimal drying process, it is important to understand the nature of the material to be dried. Some material may require gentle mechanical and thermal handling.

One example of the material is bakery grist (blend of wheat or grains). This is a pre-processed dough-like-mass consist of coarsely ground cereals, intended for baking whole-meal bread. When entering the dryer, it is quite pasty and sticky. The dryer-cooler (figure 1) is expected to lower the moisture down to around 10%. The drying temperature must not exceed 50°C in order to preserve the nutritive value.

READ MORE