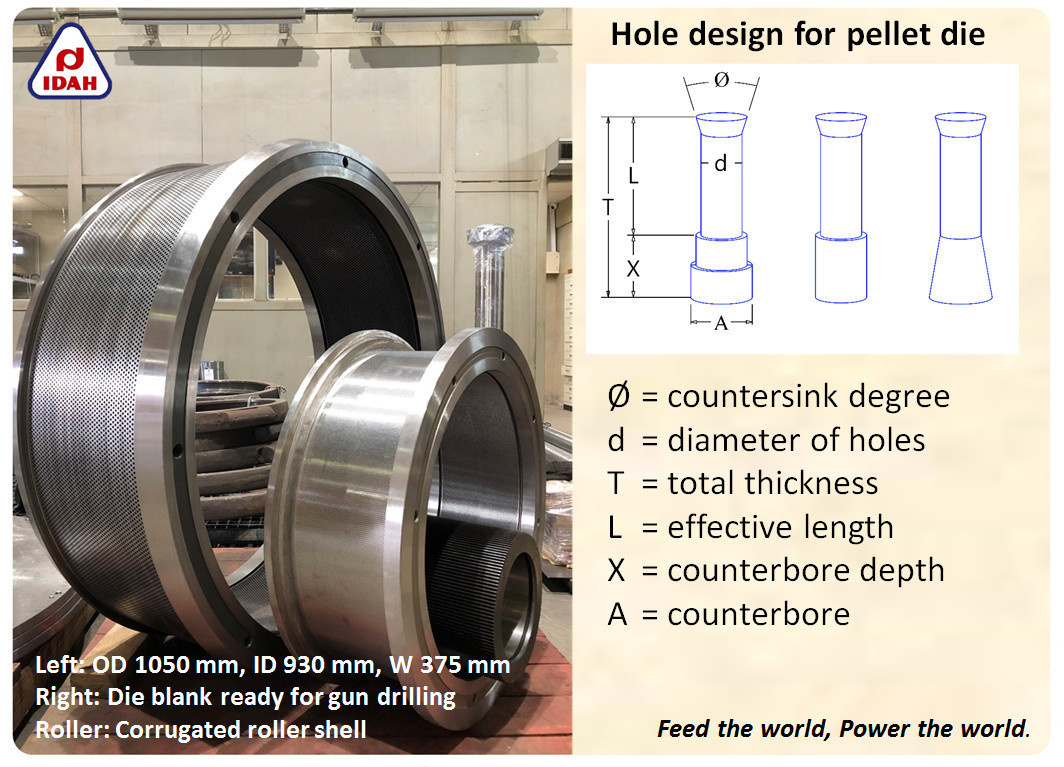

Hole design for pellet die - Relief / Counterbore

Hole Design is Important for Pelleting

According to Fairfield et al. (2005), relief is a counterbore on the outside diameter of the die. It is necessary when a thick die is required for strength but desired effective thickness is less. Three types of relief are usually used.

-

Two-step relief

Is a combination of the two straight counterbores with the second stage drilled slightly larger than the first.

It can be used when a very deep relief is required because of a very short, effective pelleting length on a thick die.

This reduces the possibility of pelleting in the relief (double pelleting). -

Straight relief

The most common pellet die, is simply a counterbore on the outside diameter that is slightly larger than the actual diameter of the pellet hole. -

Tapered relief

Can be used to replace straight relief or in combination with a straight relief to provide a two-step relief.

It removes less metal and improved die strength.