Poultry Feed

The poultry feed comes in many forms. Pelleted or mash feeds are popular in the market. Both products share a similar production sequence until the mixing process. pelleted feed needs to undergo pellet mill, cooler, and sifter after the mash is prepared.

Mash feed is a form of a complete feed that is finely ground and mixed so that animals or birds cannot easily separate the essential nutrients. The purpose of feeding mash diet is to provide a well-balanced diet, give greater growth unification, less death-incurred loss also feeding mash feed is more economical. When producing mash feed, the material undergoes pre-grinding before mixing and packing.

Pelleted feed is the continuation of mash feed. The purpose of pelleting is for easy transport and feeding. The nutrient value in every pellet is the same, so farmed animals will consume all the good nutrients incorporated inside the pellets.

READ MORE

Fish Feed

In order to support provide a balanced and stable feeding for the farmed fish, many producers have shifted to manufactured pellets. Based on the behaviour in the water, fish feed can be divided into floating feed, slow-sinking feed, and sinking feed. IDAH offers you extrusion and pellet mill to produce high quality fish feed.

READ MORE

Technical Support

Making profitable feed or food cannot be determined by how single machinery performs. Moreover, we need to consider the adequate process flow, local-based formulation design, and plant management that covers quality assurance, equipment operations, and maintenance. IDAH expert teams help to provide technical support for your industry.

READ MORE

IDAH Innovation Center

At IDAH, we understand that innovation grows from collective wisdom and experience. /

IDAH’s Innovation Center, an extrusion research lab, fosters an environment of innovation through open experimentation: providing direct hands-on access to industry experts and machinery. We can develop a competitive and innovative product with you.

READ MORE

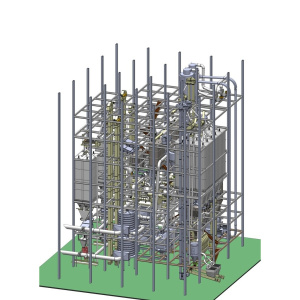

Turnkey Projects

IDAH has completed over 300 turnkey projects in 21 countries since 1974. We have enabled our customers to experience rapid growth by using our processing machines and complete plant solutions. These customers included the top 10 leading feed companies in Asia.

IDAH applied a 3D design program to simulate the process flow, to reduce the time and money needed while manufacturing machines, constructing machine towers, and machines installation. IDAH machinery and spare parts are produced with optimal design and conforming the accepted standards of safety and quality, providing premium quality and reliable products. Not only standard machinery, but IDAH also provides customizable machines for customers.

READ MORE